Click Here to View This Page on Production Frontend

Click Here to Export Node Content

Click Here to View Printer-Friendly Version (Raw Backend)

Note: front-end display has links to styled print versions.

Content Node ID: 426650

GE Aerospace is readying for the entry into service of its GE9X engine, which it describes as the “future of widebody” aircraft. According to the company, the engine, which was certified in 2020, has undergone one of its most stringent test programs, having completed 17,000 hours of testing, including 27,000 cycles.

Last year, it successfully underwent 1,600 hours of dust ingestion tests with no deterioration, and at the end of 2024, it completed ETOPS 3K testing—a 3,000-cycle endurance trial required for extended-range twin-engine operations. Scale production and deliveries of the engine have already begun, and a ramp-up is expected in the second half of 2025.

The 110,000-pound-thrust GE9X was purpose-built for the Boeing 777X, which is anticipated to enter service in 2026. It incorporates decades of advancements taken from across the company’s engine lines. The engine fan on the GE9X will use 16 fourth-generation composite fan blades, compared to 22 in the GE90 as installed on the 777-200ER in 1995, and the company is anticipating a 10% improvement in fuel burn over the earlier engine.

Construction of the GE9X also involves significant use of ceramic matrix composites (CMC), which the company has pioneered in aerospace propulsion use. CMC, with the same density as aluminum, made its aviation debut in the CFM LEAP engine’s outer shroud in 2016, and the company has since produced more than 225,000 of the part, which has racked up 74 million flight hours, at its Asheville, North Carolina facility.

GE invested more than $1.5 billion as the turbine engine pioneer in the material, including building its own supply chain, with a new plant in Huntsville, Alabama, to produce silicon carbide fibers, CMC’s basic raw material.

Packed at a density of 1.5 million fibers per square inch in a silicon carbide matrix and given a protective boron nitride coating, the parts are one-third the weight of the titanium counterparts they are replacing.

Lower Cost, More Durability

In addition to that weight savings, the CMC parts also have a much greater high-temperature durability than the legacy metal parts. Due to the fiber matrix in CMC—which, as a result of its inherent hardness, must be cut with diamond-tipped tools—any impact damage to the part is localized, and cracks will not propagate. The GE9X incorporates five CMC components (stage 1 shroud, stages 1 and 2 nozzles, and the inner and outer liners), incorporating 107 parts.

In preparation for its service entry, GE Aerospace has invested more than $1 billion on the MRO side in training, tools, and capacity across its network to make sure the new engine is properly supported. GE Aerospace Wales will be the company’s only overhaul facility for the GE9X, but it has also signed up Heico in China and Emirates Engine Maintenance Center in Dubai for service, to start.

In a pre-Paris Air Show media tour last month, the company showed off its global research headquarters in Niskayuna, New York, near the state capital of Albany. It is a milestone year for the center—America’s first industrial innovation facility. Established in 1900 under the watchful eye of Thomas Edison, it is celebrating its 125th anniversary and its 75th at its current campus.

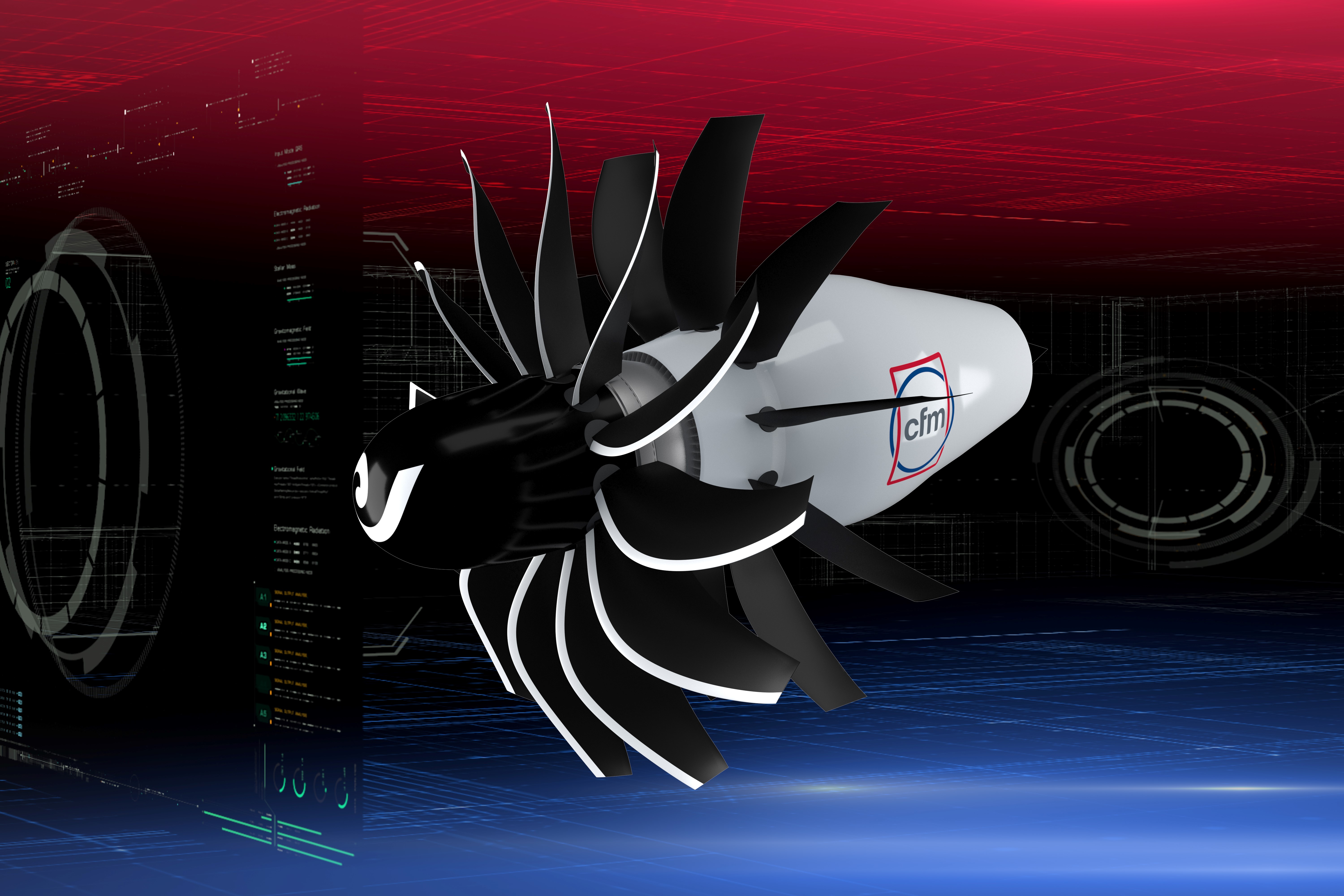

There, it also showed off the innovations that are being incorporated in its RISE (Revolutionary Innovation for Sustainable Engines) open-fan demonstrator being developed through CFM International with partner Safran. For GE Aerospace, RISE represents the single largest demonstration program in company history and its vision of a more fuel-efficient powerplant for future narrow-body commercial aircraft.

The manufacturer noted that a larger fan diameter relative to the engine core size equals a higher bypass ratio, which leads directly to engine efficiency. However, in a traditional ducted fan engine, the encasing nacelle must also increase in size as the fan size increases. There comes a point where the fan becomes so large that any high bypass benefits are negated by the drag from the surrounding nacelle. The solution, according to GE Aerospace: get rid of the duct.

It first experimented with the open-fan architecture during the 1980s with the GE36 unducted fan program. While the counter-rotating fan engine promised to deliver turbofan performance with the fuel efficiency of a turboprop, the engine was unpleasantly loud.

Revisiting the concept in 2021 with the launch of RISE, the company credits the recent evolution of “exascale” supercomputers for accelerating the program’s development. GE Aerospace’s partnership with the U.S. Department of Energy’s Oak Ridge National Laboratory has given it access to Frontier, one of the world’s fastest and most powerful computers. That has enabled it to conduct countless virtual tests of fan blade shapes to deliver not only the best fuel efficiency and thrust, but also a vastly improved acoustic signature. The company has found that once manufactured, the performance of the actual components exactly matches the virtual models.

The manufacturer, which has 44,000 commercial engines in service globally—including those from its CFM joint venture—expects to have a RISE engine on wing by the end of the decade.