Click Here to View This Page on Production Frontend

Click Here to Export Node Content

Click Here to View Printer-Friendly Version (Raw Backend)

Note: front-end display has links to styled print versions.

Content Node ID: 427526

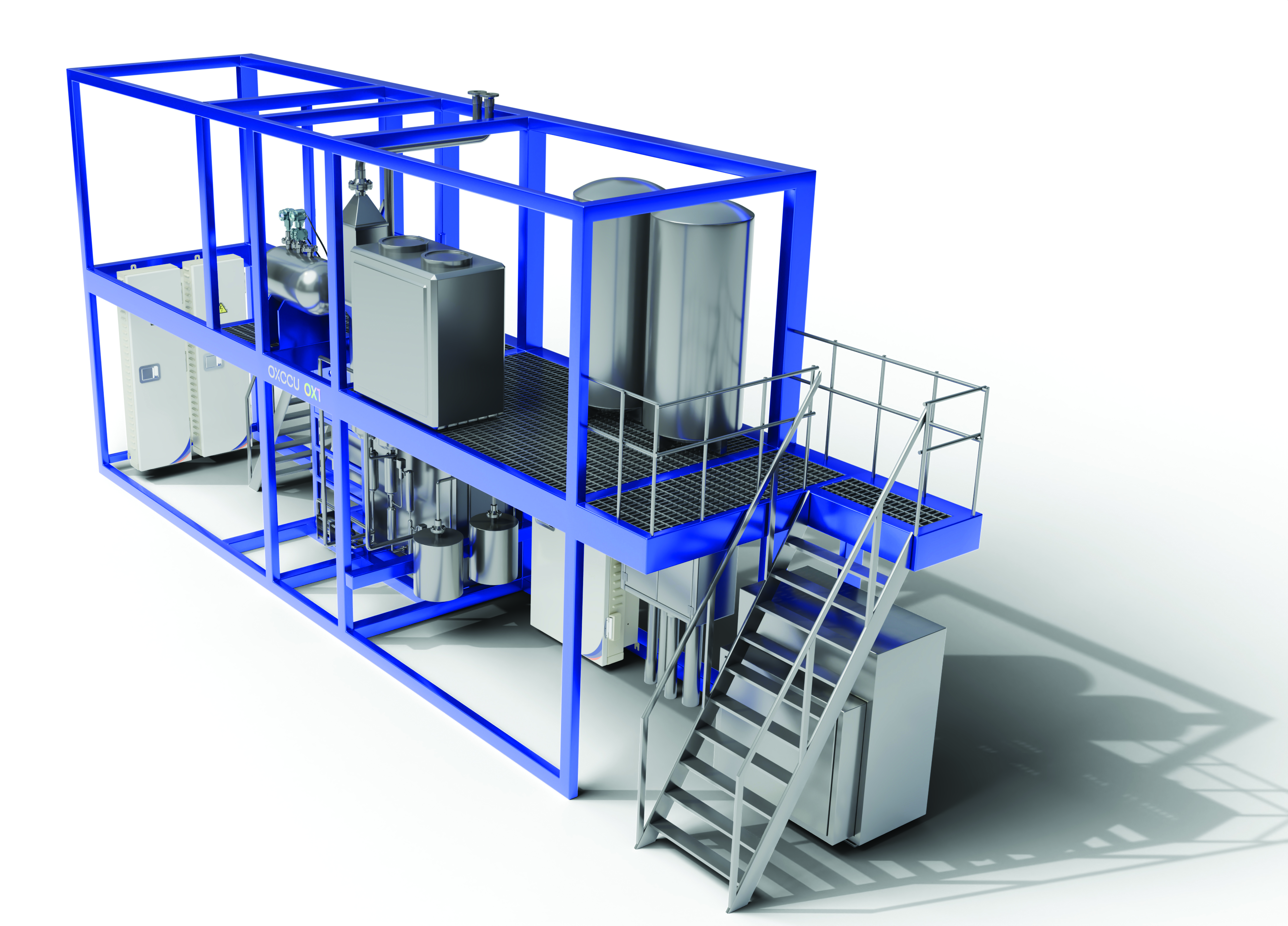

OXCCU, a start-up founded almost four years ago by Oxford University chemical engineers, says it is on track to convert biogenic waste carbon and hydrogen into affordable sustainable aviation fuel (SAF) by the end of the decade. The UK company opened its OX1 demonstration plant at Oxford Airport and now has the capacity to produce around a kilogram (1.2 liters) of fuel each day.

According to Andrew Symes, the company’s CEO and co-founder, OXCCU’s business model is to license its catalyst and reactor technology to convert blends of carbon dioxide and/or carbon monoxide and hydrogen sourced from waste biomass waste carbon into SAF. He told AIN that with the right partnerships in place for licensed production and distribution, the SAF could be available to aircraft operators in 2028 or 2029.

The company is now building a larger OX2 plant to scale up both power-to-liquid and gas-to-liquid production processes. This facility is expected to have an initial production capacity of between 10 and 30 liters each day when it opens next year. This will allow fuel testing to be expanded.

Nonetheless, Symes is concerned that pressure from some elements in the green energy movement could lead to progress with SAF being deprioritized in favor of investing in solar- and wind-generated power, and electric vehicles. “The challenge though is that aviation emissions are growing enormously and if we don’t dedicate any effort to it now we won’t have a solution when we need it,” he commented. “Aviation is behind other sectors so we have to do both.”

The European Union’s Refuel EU legislation is intended to be a catalyst for expanding the use of SAF. It sets a goal of increasing SAF’s share of fuel delivered to operators at EU airports from 2% this year to 70% in 2050, backed by a series of mandates to increase production and distribution that started going into effect from January 1.

However, Refuel EU is not without its detractors in the aviation industry. For instance, business aircraft operators have complained that the rules are unrealistic as SAF is not sufficiently available at the smaller airports they tend to use. The European Business Aviation Association is also pushing for book-and-claim arrangements to be officially accepted as part of the requirements.

“I think Refuel EU is a necessary piece of legislation,” Symes said. “Everyone will have certain things they want to change. I have very specific ones. [Firstly], that they take into account the lifecycle emissions of fuel in the amount of credit you get rather than just having a threshold you have to be under and secondly that they drop the requirement for specifically biogenic CO2 or direct air capture by 2040 for power to liquid fuel.”

SAF Costs Must Decrease

In Symes’ view, the biggest obstacle to SAF adoption is cost because most of the currently available processes for making the fuel are insufficiently mature. He told AIN that innovating to make SAF more affordable is a more effective way to address the cost challenge than to seek government subsidies or expect consumers to pay more to fly.

This is why OXCCU, which stands for Oxford Carbon Capture Utlilization, has chosen to focus on maturing fuel production from waste carbon. “It’s around focusing on innovation in these pathway that gets costs down and its getting costs down that will drive [SAF] adoption,” Symes said. “If you drive down the cost of SAF and the emissions reductions are high, there won’t be criticism.”

This progress is both time- and capital-intensive, with deep-tech companies like OXCCU requiring backers willing to wait for returns on investment. Symes acknowledged that access to venture capital for aviation decarbonization initiatives in aviation is harder to day, in part because of U.S. President Donald Trump’s general hostility to green energy. To date, the UK company has raised £20 million ($27 million) through seed capital and a Series A funding round.

“We’ve got a more difficult venture capital situation and the current U.S. administration has made it more difficult because there is less U.S. clean tech capital, but the corporates [in the aviation sector] are still desperate for a solution,” Symes said. “Companies that have distinctive technologies will still get funded but they need to be cleverer about how they use capital and desrisk technology.”

OXCCU expects that Europe’s aviation industry will continue to be the first movers in boosting SAF use. It is now focused on lining up partnerships with larger corporate partners to help achieve the breakthrough in cost and availability of waste carbon-based fuel.