Click Here to View This Page on Production Frontend

Click Here to Export Node Content

Click Here to View Printer-Friendly Version (Raw Backend)

Note: front-end display has links to styled print versions.

Content Node ID: 402827

Advances in small solid-state hard drives and recording technology allow flight data recorders (FDR) to capture gigabytes of continuous data from engines, airframes, avionics, datalink, and voice transmissions. “The SRVIVR25™ family of recorders have been developed with robust memory improvements to allow for the recording of as many aircraft parameters as possible,” said Steve Alwin, Vice President Engineering for L3Harris Commercial Aviation Solutions. “The entire family provides over 140 hours of recorded data when installed as a flight data recorder.” However, some operators consider the FDR a static piece of equipment accessed only during compliance checks and accident investigations, while others monitor FDR data to gain valuable insights that save time, reduce costs, and increase safety.

“Apart from a person’s professional attitude to aviation, flight data monitoring (FDM) is the most important tool in the flight safety arena,” said Mark Eynaud, Safety Manager for Malta-based ElitAvia. “It’s a very good way of monitoring the operation as it unfolds from the flight deck and identifies any risks.”

FLIGHT DATA MONITORING FROM L3HARRIS

ElitAvia uses L3Harris Flight Data Connect as its FDM service provider on its mixed fleet of Global, Challenger, Gulfstream and Falcon aircraft. As an aircraft charter and management company that does not own the aircraft that it operates, ElitAvia has little control over the equipment on-board, so to monitor their flight data they need an easy to use program that works with different FDRs.

“We have an L3Harris laptop onboard the aircraft configured with the required software,” said Eynaud. “The laptop connects to the quick access recorder, downloads the data in ten minutes or less, and then using that same laptop, the data is uploaded through Wifi to the L3Harris servers. We get to see the data almost immediately, and the graphics are very good.”

According to Chris Jesse, Senior Manager of Flight Data at L3Harris, business and general aviation operators make up nearly half of the company’s flight data services customers as they can reap the same data monitoring benefits as airlines without purchasing expensive analytical software or requiring an analyst on staff.

“Let’s say a captain reports a suspected flap overspeed,” Jesse said. “The flight data makes its way to our servers via manual or wireless upload, and we process the data extremely fast. By the time you make yourself a cup of tea and return to your mobile device your data is ready for you to diagnose whether that flap overspeed was legitimate or not. Do you actually have to ground the aircraft to get the flap inspected, or can you release it straight away? You can get those factual answers very quickly using FDM.”

While solving single point maintenance issues is one benefit of using FDM, the program is most powerful when identifying trends across a fleet. Kjetil Dahlshaug, Flight Data Monitoring Manager and Boeing 737 captain for Norwegian Air Shuttle ASA, used the FDM program to solve a problem involving tail strikes on Norwegian’s 737 fleet.

“We experienced some tail strikes a couple of years ago on 737s during takeoff,” said Dahlshaug. “Using the FDM program, we saw a trend of faster rotations. The rotation rate during takeoff increased slowly year by year until it reached the point of the tail striking the runway. As a result, we did some focused training on it. Afterwards we could see the rotation rates going down again and we haven’t had a tail strike since.”

Dahlshaug says that solving the tail strike problem was a combined effort between the safety office, flight operations, and training. While only he and a handful of other safety and operations personnel have direct access to the data due to strict confidentiality protecting crew privacy, they can generate reports and provide limited guest access to data without revealing crew names.

“We’re all trying to develop new ways to use the system because there are enormous amounts of data,” said Dahlshaug. “We’re looking at how to generate individual pilot reports—while maintaining confidentiality—to give more feedback to pilots on all aspects of their flying, not just when they’re exceeding limits or doing something wrong.”

The proprietary L3Harris program automatically checks about 1,000 event parameters as defined by ICAO safety management system (SMS) guidelines. It notifies the operator of any exceedances through L3Harris’ customizable web-based portal, and by email or text message if set. L3Harris worked with Norwegian to customize a few parameters—such as steep approaches—that were constantly generating event reports during ‘normal’ flights.

“Northern Norway has many nonstandard airports requiring steep approaches in mountainous terrain and short or slippery runways,” Dahlshaug said. “We had to adjust some of the FDM thresholds to fit those operations.”

NOT JUST DATA—PEOPLE TOO

Charles Auty, Flight Data Monitoring Coordinator and Saab 2000 captain for Eastern Airways, frequently calls on his L3Harris analyst, Andy Robinshaw, to help spot trends and troubleshoot problems. Based at the U.K.’s Humberside Airport, the regional carrier uses a mixed fleet of jets and turboprops on short-haul flights, and Auty is currently the only person authorized to directly access the FDM data.

“The relationship is really helpful because I don’t feel worried in any way about asking Andy any question,” said Auty. “There’s no question too silly. He always responds in a professional way that allows me to develop my understanding of the FDM system.”

Auty and Robinshaw recently worked together to determine the reason behind an increase in high taxi speeds.

“We noted a trend in increased taxi speeds in the Embraer fleet,” Auty said. “It turned out that after landing on a specific runway, the crew have to make a 180-degree turn and then vacate quite a long way down the same runway, downhill and with a tailwind. We have been working with the crews to manage that high-speed taxi to balance brake wear with maintaining aircraft control. “

Offering both automated data processing and expert analysis sets L3Harris apart from many other FDM companies. L3Harris uses patented processing tools to identify major spikes, data shape, and relationship correlations between different parameters ensuring the highest data quality levels. After the raw data is processed and populated into the software in a matter of minutes, human analysts take a deeper look at the data to provide key insights within a few hours.

“By automating the data upload and processing, we cut down the time to get results from days or weeks, to just a matter of minutes, and the accuracy is better, which builds trust in the system,” said Jesse. “While operators can view their own data, many of our customers rely on our expertise for their FDM and FOQA programs. We free them up to do the flying and take safety actions, while we look after all the backend processes such as data analysis, developing new software capabilities, managing the infrastructure and backups.”

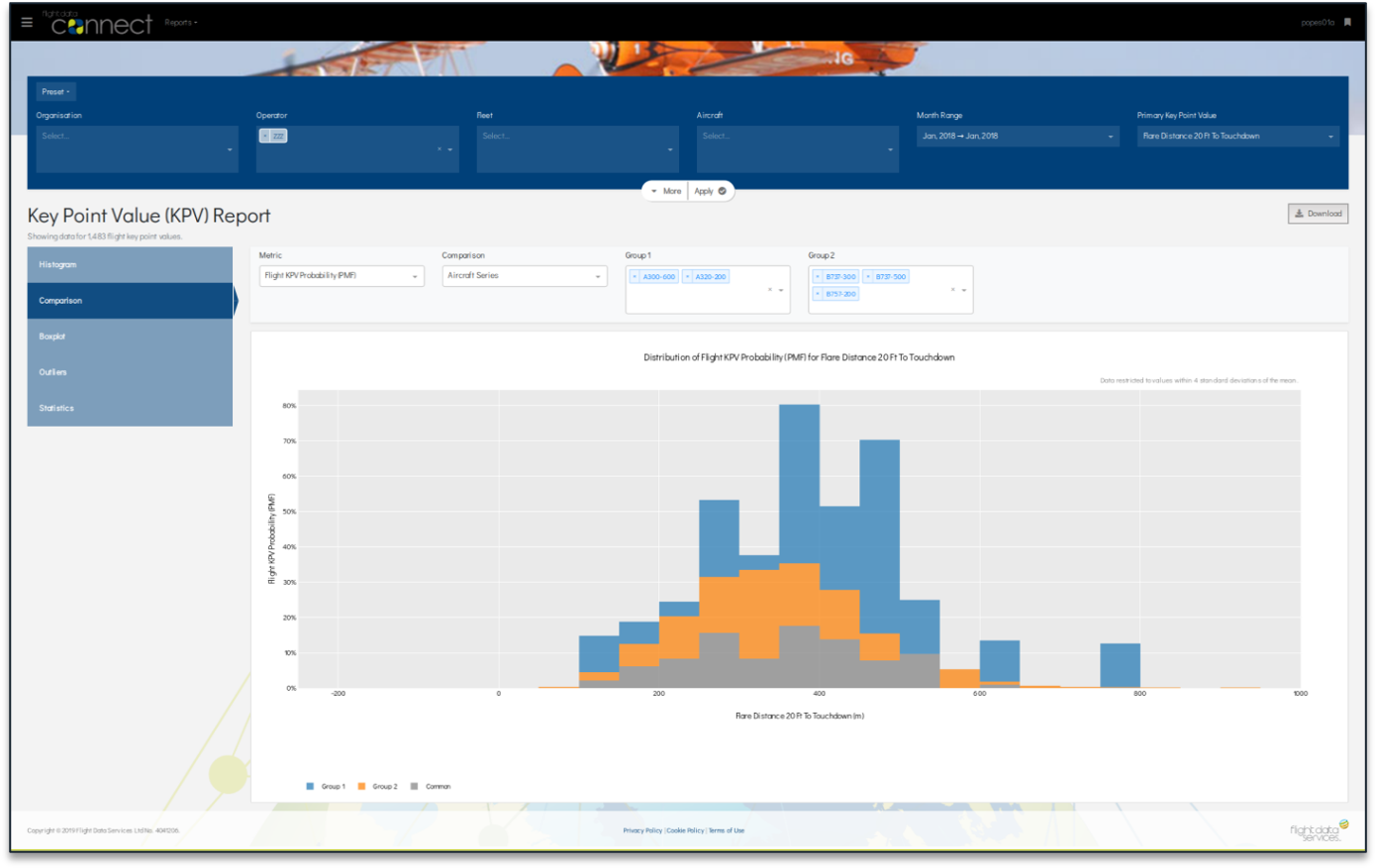

While airlines can often find trends across their fleets, business aircraft operators would typically only generate statistics from one or a few aircraft they operate. With the L3Harris Flight Data Connect service, customers have the option to join the IATA Flight Data eXchange (FDX) program and benefit from more than 20 years of accumulated de-identified data of all aircraft sizes to help compare their operations and spot trends or departures from normal.

“Presently we have 16.4 million flights from 155 different aircraft types in the database,” said Jesse. “A small operator can monitor their unstable approach rates and see that other operators in the same aircraft type have fewer events, and then drill in to find causal parameters. They can’t see enough information to identify the other operators, but enough to benchmark their operation against others and take action.”

While L3Harris can analyze data from nearly any FDR, the company just launched a new series of extended duration FDRs and Cockpit Voice and Data Recorders (CVDRs) that can further enhance an operator’s FDM program. Dubbed SRVIVR25™, the new series of L3Harris FDRs and CVDRs provide at least 25 hours of voice and a minimum of 140 hours of flight data recording in a crash-protected case that features several improvements over previous generations of CVDRs.

“L3Harris has taken a 360-degree approach to flight data monitoring and analysis,” said Darshan Gandhi, Business Development Manager for avionics at L3Harris Commercial Aviation. “We manufacture the recorder to meet current and upcoming global standards, provide means for maintenance and safety personnel to access the data through a remote data interface and ground support equipment, and then provide analysis tools and services to allow operators to use that data to improve their operations.”