Click Here to View This Page on Production Frontend

Click Here to Export Node Content

Click Here to View Printer-Friendly Version (Raw Backend)

Note: front-end display has links to styled print versions.

Content Node ID: 408570

One thing Duncan Aviation is proud of is the freedom team members have to be creative and look for new ideas. Similar to Duncan Aviation’s Interior Innovative Solutions™, which include hydrographic finishes, the company’s Upholstery team members found a more cost-effective way to control quality, creativity, and turntimes for the seats in customers’ aircraft.

Upholstery Team Leader Travis Smith realized how much extra time and money it took to send seat panels to outside vendors for certain specific customization processes. Because innovation is a priority for Duncan Aviation, Smith sat down with his team and researched possible ways to bring these projects in-house. After identifying potential technology and attending automotive interiors trade shows, Smith and his team found a solution.

Perforation, Multicolor Sewing & Embroidery

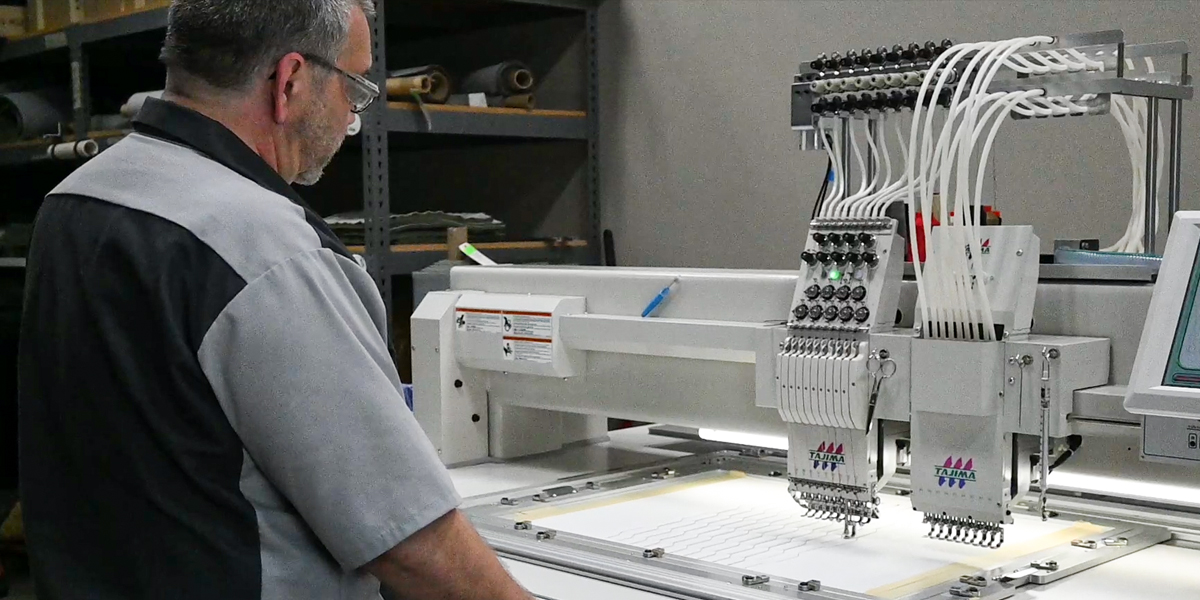

The newest addition to the Upholstery Shop at the Duncan Aviation full-service facility in Battle Creek, Michigan, is a state-of-the-art machine that allows the company to create perforation, multicolor sewing, and multicolor embroidery on aircraft seats and panels.

“This machine allows us to control the quality and turntimes, and lets our imaginations run wild with possible designs,” says Smith. “The designs are pretty close to endless with what we can do on quilted panels.”

Before the machine arrived at Duncan Aviation in early 2022, similar work was outsourced and done with a similar machine, or had to be completed by hand. This made it difficult to give customers the creative freedom to choose the stitching and designs in their seats. The capabilities provided through the new technology and training allow the artisans at Duncan Aviation to better control the design and tailor it to each individual seat with pinpoint accuracy and precision. Upholstery technicians are able to see on a computer screen where individual lines will hit and how the designs will look, giving them the ability to make minor alterations.

“Because we no longer have to send the seat panels out of house or complete it by hand, the time savings are huge,” says Smith. “We can complete 20 panels in a couple of days with this machine, compared to a couple of weeks using the old methods. The result is dramatically reduced downtimes while maintaining Duncan Aviation quality.”

Upholstery Master Specialist Todd Bartholomew says it’s all about working smarter with technology.

“Rather than relying on tedious, old school ways of doing this by hand, we found a way that helps us move forward in a more efficient manner,” Bartholomew says. “Having this unique CNC machine in-house allows our Design and production teams to offer custom quilting, perforation, and embroidery to our customers while controlling the lead times to ensure we meet downtime needs.”

The new technology is currently helping the team produce custom cabin seat inserts in-house, but Batholomew and his team are not stopping there.

“We are working to customize throw rugs, entry runners, lower sidewall accents, and company logos,” he says. “Customers will now be able to personalize their aircraft interior components to a new level.”

The Process

When a customer chooses customized, quilted patterns, the first step is to have a Duncan Aviation Aircraft Designer send Bartholomew a conceptual design. He then draws it on computer and converts the drawing into the machine’s language with all the parameters it needs. A test panel is then completed. After the test panels are perfected, Bartholomew creates a finished design sample for the customer to see and approve. After approval, the team runs the final panels and get them inspected before they are installed in the aircraft.

Innovation is Contagious

Interior Manager Kody Keller says that introducing new technology and equipment into the shops allows team members to remain curious and helps evolve Duncan Aviation’s capabilities and talents to offer the best products to the industry.

“Innovation is contagious and it has always been a part of the Duncan Aviation culture,” says Keller. “Continuous improvement helps us work smarter, not harder, which helps with team morale, overall fulfillment of our team members, and customer satisfaction.”