Click Here to View This Page on Production Frontend

Click Here to Export Node Content

Click Here to View Printer-Friendly Version (Raw Backend)

Note: front-end display has links to styled print versions.

Content Node ID: 419198

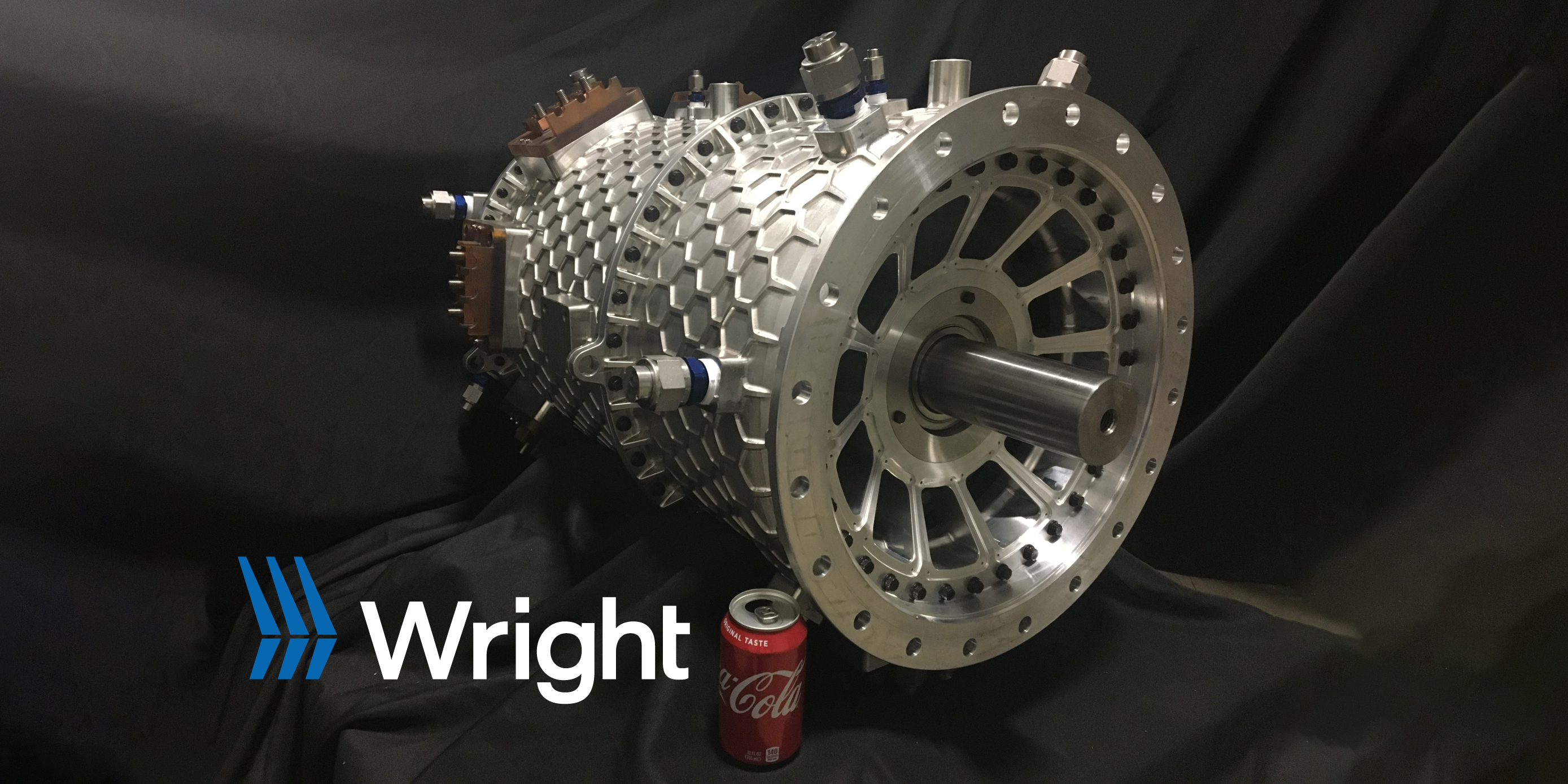

Wright Electric has produced and started testing the two-MW electric motor it is developing for trials on a single-aisle airliner in partnership with low-cost carrier EasyJet. The U.S.-based company aims to begin ground testing by the end of 2021 and to flight test at altitudes of 40,000 feet in 2023. It hopes to have an electric powertrain in commercial service on an aircraft such as the Airbus A320 by 2030, following a full program launch in 2024.

The next phase of the project, which started in 2016, will see the motors integrated with an inverter that Wright has developed. The company will also conduct high-altitude chamber testing of the equipment to gather data for future aircraft certification work.

Wright intends to open a dedicated laboratory for the program somewhere in the U.S. later this year with the capability to test high-voltage motors and inverters. The company has received funding from NASA and the U.S. Department of Energy, as well as from the Air Force and the Army.

EasyJet has previously expressed a willingness to be an early adopter of electric propulsion for its narrowbody airliner fleet. Along with Mexican airline VivaAerobus, it has held consultations with Wright Electric over its program.

“We are delighted to see the promising and significant progress of Wright Electric’s program, in what will be groundbreaking technology,” commented EasyJet’s director of flight operations, David Morgan. “EasyJet remains committed to more sustainable flying and we know zero-emission technology is where the solution lies for the industry.”

Still to be fully resolved is whether Wright’s electric powertrain would be retrofitted to existing airliners or whether it would be integrated with an entirely new aircraft. The company has released a concept drawing of an aircraft called the Wright 1, which would have 10 of the 2MW motors, delivering equivalent power to that needed for existing A320s. It says the motors are scalable with power ratings ranging from 500 kW to four MW.

Whether or not Wright actually assembles the airplane or contributes its technology to a program by another airframer remains undetermined, however. “We're right now having those discussions about who's going to do the manufacturing and things like that,” Engler told a FutureFlight sister publication in May. “I think we're heads down on proving out that the motors and inverters work on the ground and then at 40,000 feet, and I would say everything else is a future decision.”

Wright claims the technology will deliver a 99.5 percent efficiency level, representing a sixfold improvement over current aviation inverters and resulting in significantly lower thermal management loads. In May, following initial testing of its inverters, the company said the propulsion system will carry a power density of 30 kW/kg. Given that currently available technology delivers only between 10 and 20 kW/kg, such an increase would result in weight savings equivalent to carrying an extra five to 10 passengers on each flight in a standard single-aisle airplane.

Engler said that Wright’s electrics could apply to any of three kinds of propulsion systems: full electric, hybrid electric, or hydrogen. But whatever shape the final product takes, it will require a design approach that differs dramatically from a typical jet-fuel-powered machine.

“We think of ourselves as experts in, number one, motors and inverters, and, number two, aerodynamically and efficiently configuring the airplane using those motors and inverters…If you look at, for example, a Tesla…a Tesla isn't just a Mercedes where you take out the engine and you put electric motors. To the passenger, it’s the same, but under the hood, it's very different.”

The Albany, New York-based company was formed in 2016 to develop an electric power system for a 186-seat airliner that would fly to a range of 800 miles. The 15-employee start-up has financial backing from Y Combinator and the Clean Energy Trust, as well as from venture capital groups and private investors.