Click Here to View This Page on Production Frontend

Click Here to Export Node Content

Click Here to View Printer-Friendly Version (Raw Backend)

Note: front-end display has links to styled print versions.

Content Node ID: 419462

Advanced materials group Solvay this month launched a partnership with Wichita [Kansas] State University’s National Institute for Aviation Research (NIAR) to develop technology solutions for companies for new types of aircraft, including eVTOL models. Solvay is deploying scientists and engineers to work with a team from NIAR in its Advanced Technologies Lab for Aerospace Systems (ATLAS).

The initiative is Solvay’s latest move into the advanced air mobility sector, where it is already a partner in Vertical Aerospace’s VX4 eVTOL program. “We’re working in the aviation sector to enable a step-change in the performance of vehicles, focusing on three factors: engineering, aerodynamics, and propulsion,” Marc Doyle, Solvay’s executive vice president for aerospace and defense, told FutureFlight. “We want to be part of advanced air mobility to make it work and also because the learnings that come from this will always have a positive applicability to the rest of aerospace.”

The company’s priority is to contribute to the structural weight savings that will be critical to the success of the new electric aircraft. In addition to providing composite materials like high-performance polymers for aircraft structures and fuel systems, and high-performance adhesives, Solvay has experience in the manufacturing of batteries and their casings, largely from its work in the automotive sector.

“Every pound matters so much more to an electric vehicle, and we’re trying to get every bit of range and payload we can for our partners,” said Stephen Heinz, Solvay’s head of research and innovation for composites. “Traditional aviation is in a bit of a down cycle now and we need new platforms, like advanced air mobility, to drive some innovation. What we do will be very relevant to the next generation of civil aircraft. We like to partner with OEMs to help them along the materials journey and how they move into low-initial rates of production and then scale up.”

Like weight, safety is critical with regard to the materials selected and how they are used. Solvay has experience in guarding against threats such as electromagnetic thermal runaways and the need to protect batteries and other systems. “We have a good starting point here with programs like the [Boeing] 787 and the [Airbus] A350,” said Heinz.

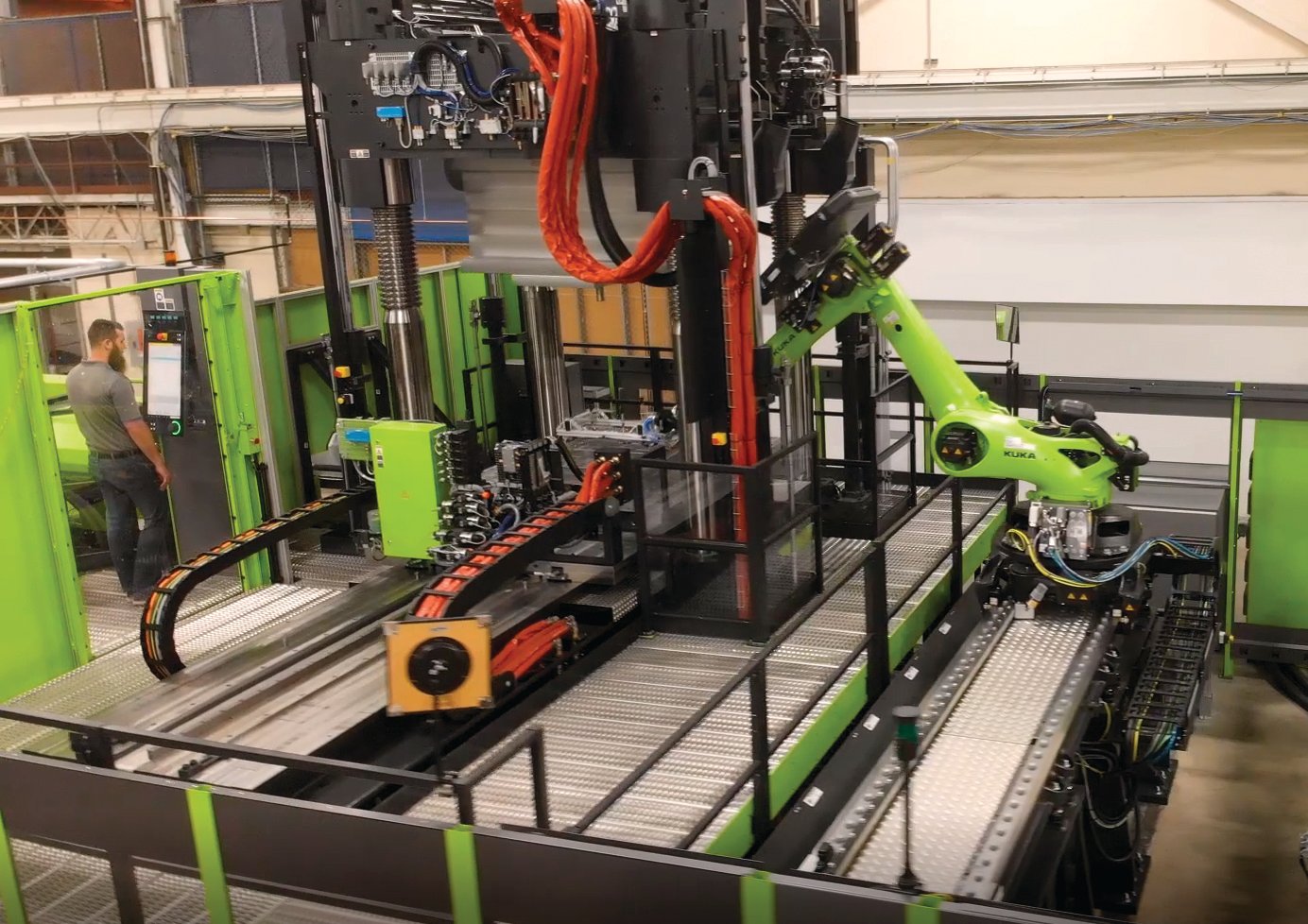

The 150,000-sq-ft ATLAS facility in Wichita has plenty of space for developing prototypes and for testing the durability and strength of aviation components. It provides an environment where airframers can assess options for improving their aircraft.

Solvay and NIAR have already begun work at the site with undisclosed customers. “We’re thrilled to have Solvay onsite to provide material guidance and support on a variety of aerospace manufacturing applications,” said Wichita State University’s NIAR executive director, John Tomblin. “Solvay scientists work closely with our researchers to exchange ideas and results.”