Click Here to View This Page on Production Frontend

Click Here to Export Node Content

Click Here to View Printer-Friendly Version (Raw Backend)

Note: front-end display has links to styled print versions.

Content Node ID: 419481

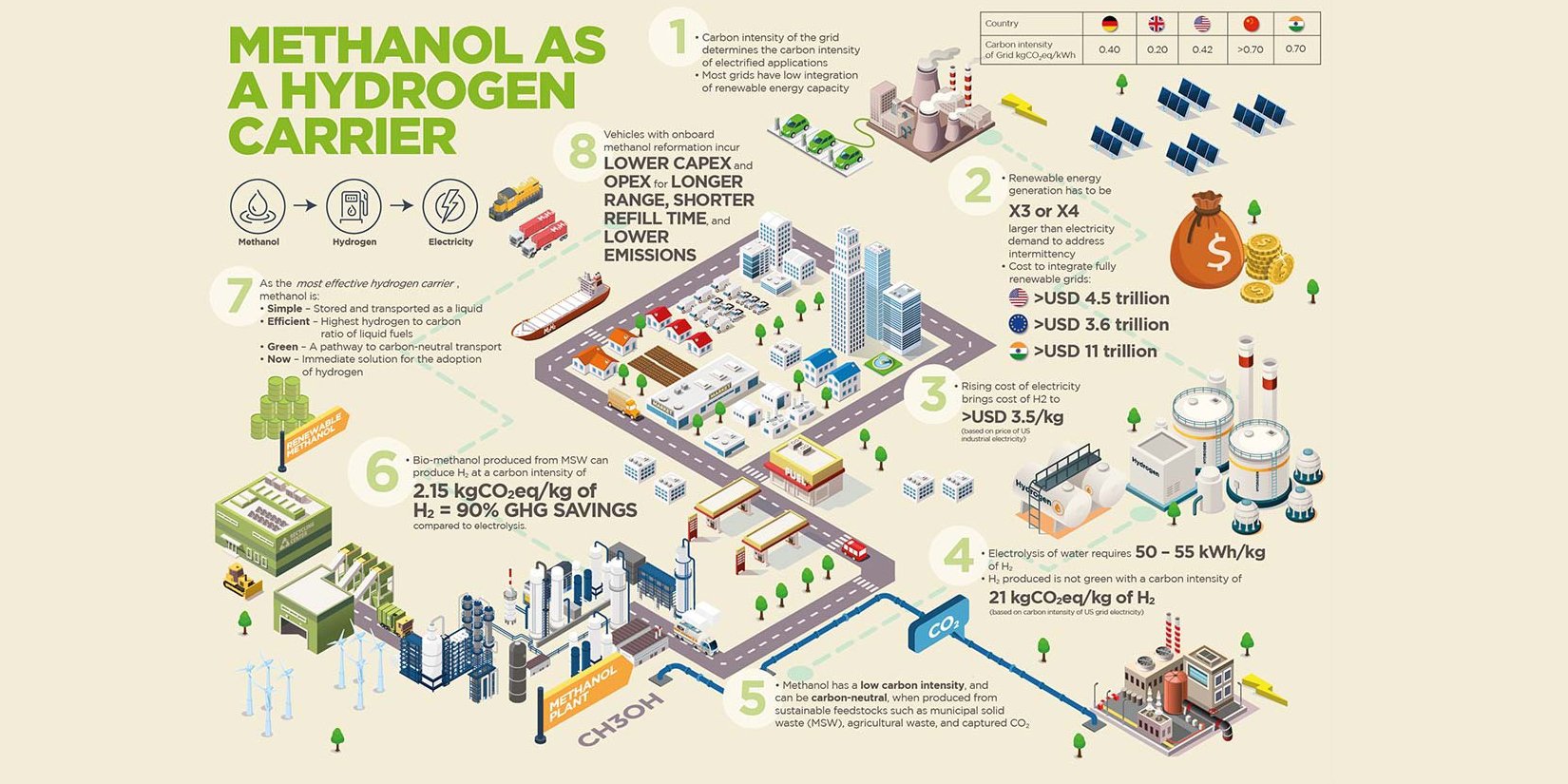

There’s been a lot of talk about the potential for hydrogen to turn aviation from the environmental bête noire into a green god, and for good reason. As a clean fuel, hydrogen has the potential to substantially lower aviation’s carbon footprint. Furthermore, by offering significantly more range than battery-electric aircraft, it stands to play a huge role in enabling advanced air mobility.

While the benefits of hydrogen have been well covered, however, what hasn’t been as thoroughly discussed is how it is made. According to the Office of Energy Efficiency and Renewable Energy, hydrogen can be produced from a variety of resources, some of the most common being natural gas, nuclear power, biomass, solar energy, and wind power.

But methanol? Some in the energy innovation field are identifying the liquid as a potential game-changer in the competition to make zero-carbon fuel viable.

“Methanol is a very attractive, if not ideal, feedstock for making hydrogen,” said Dave Edlund, founder and CEO of Element 1, a technology development and licensing company developing scalable, very low-cost hydrogen generators.

As Edlund explained, when it comes to producing hydrogen, methanol offers unique advantages. For example, methanol is a liquid under all reasonable environmental conditions, meaning it won’t freeze, even when mixed with water. It also has more useful hydrogen in it volumetrically than what one can get from liquid hydrogen.

“It’s easily transported and, because it’s a liquid, you can use conformal fuel tanks and don’t need to worry about storing it under pressure,” Edlund told the Vertical Flight Society’s recent Transformative Vertical Flight conference in San Jose, California. “Comparatively speaking, methanol’s fire risk is very low, it can be mixed with water and, if spilled in the environment, it will rapidly biodegrade.”

Furthermore, fuel cell hydrogen generation technology can already meet the requirements of battery recharging and hydrogen refueling—all without the infrastructure challenges of other power systems.

“If you’re talking about battery recharging, it’s a really simple equation—you start with hydrogen, you run that hydrogen through the fuel cell, and the generated electricity can be used to recharge the battery,” said Edlund. “The play here is you can do this with a very short project timeframe and with very low investment costs, and you end up with a charging infrastructure that is completely disconnected from the grid.”

The process for hydrogen fueling is equally simple. Essentially, you take the methanol, convert it to hydrogen, and then dispense it into suitable containers for use on vehicles. “The advantage is that we can make hydrogen from methanol for just a few dollars per kilogram at the point where the hydrogen is going to be used, which results in a 50 to 70 percent reduction in cost of hydrogen per kilogram,” Edlund added.

In addition to its costs and efficiency advantages, methanol, when created from renewable resources, has the potential to substantially reduce, if not negate, carbon emissions. According to Edlund, green methanol is made from carbon dioxide or carbon dioxide mixed with methane that, under other circumstances, would be emitted into the atmosphere. Instead, by converting this feedstock into methanol, one effectively removes the carbon dioxide (CO2) and/or methane from the atmosphere.

“Let’s not overlook the significance of the methane component here, as methane is 28 times more potent than CO2 as a greenhouse gas,” said Edlund. “By preventing this methane from being emitted into the atmosphere, converting it into methanol and then hydrogen, we essentially create a carbon cycle that allows us to achieve negative carbon intensity—that’s a powerful position to be in.”

For Element 1, all of this makes methanol an attractive means of producing hydrogen onboard a hybrid-electric aircraft. “Our goal is to put a liquid methanol-water mix onboard an aircraft,” said Edlund. “That mix would then be converted to purified hydrogen on demand and fed to the fuel cell that then works with the batteries to provide electric power to the propulsion motor.”

However, Edlund did caution that an onboard methanol-to-hydrogen system is not feasible for every type of aircraft. “We have to be looking at applications that are sensible for this type of technology and not try to shoehorn it into everything that needs electricity,” he stated.

The main issue is weight and space, meaning onboard hydrogen generation may not be a viable solution for small aircraft. “As energy demand increases, you reach a point where onboard hydrogen generation rapidly starts to make sense, which explains our focus on advanced aircraft that lean towards megawatt-hours,” said Edlund.

Despite these challenges, Edlund is adamant that the future for methanol’s use in aviation is bright. “The bottom line is that methanol is a viable means for creating low-cost, carbon-free hydrogen,” he concluded. “And because there’s no recharging infrastructure prerequisite, it’s ready to be used now.”