Click Here to View This Page on Production Frontend

Click Here to Export Node Content

Click Here to View Printer-Friendly Version (Raw Backend)

Note: front-end display has links to styled print versions.

Content Node ID: 402736

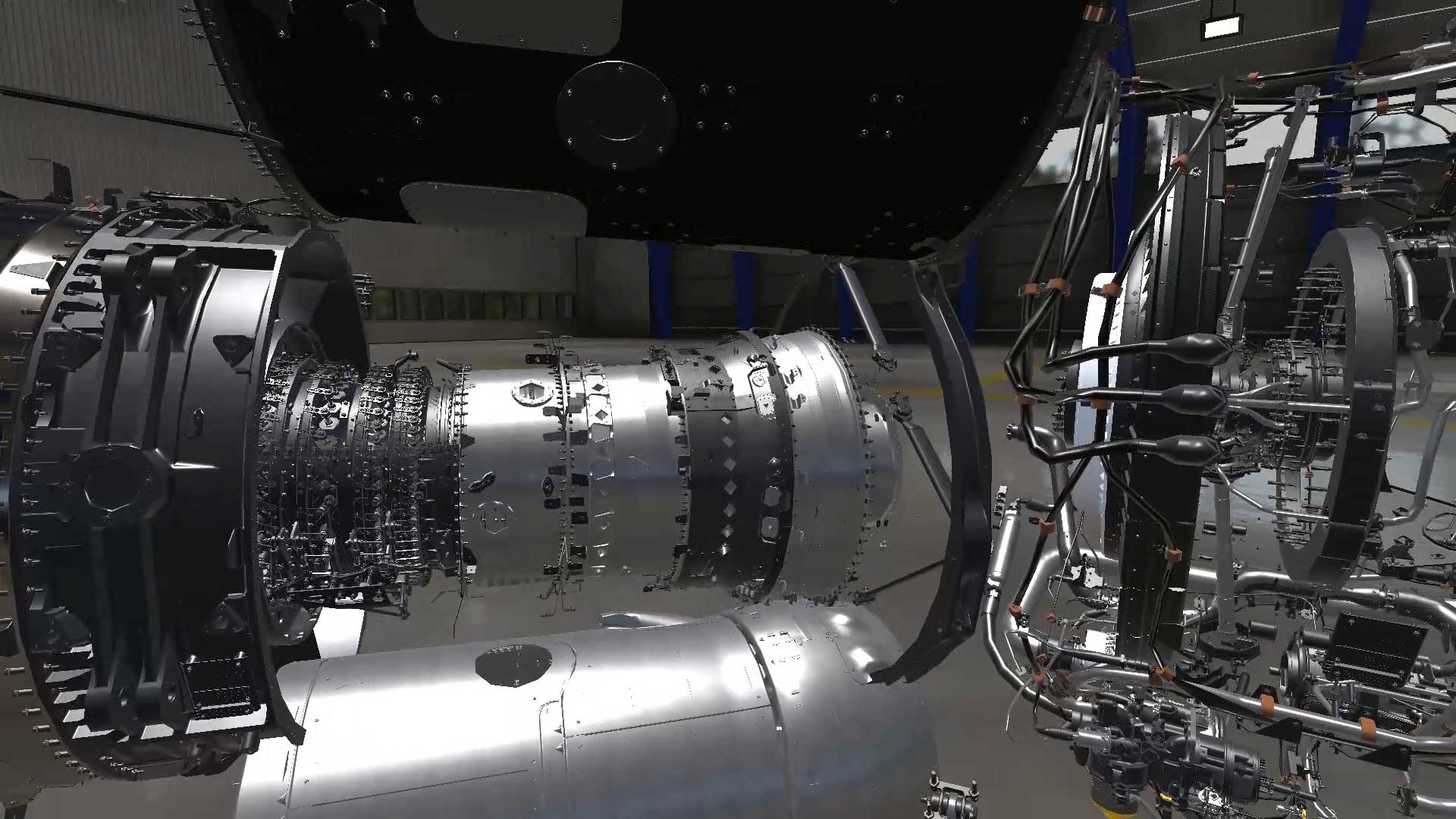

I’m standing inside a big hangar, looking at a Gulfstream G650 parked on the polished concrete floor. The G650’s left engine cowl is open, revealing a gleaming Rolls-Royce BR725 turbofan engine surprisingly unblemished with the dirt smudges that powerplants normally accumulate. I try to walk toward the maintenance stand next to the engine and after a few steps bump into something on the floor. But it isn’t something in the hangar, and I’m not really in a hangar. I’m inside a virtual reality (VR) world created by Rolls-Royce for BR725 technician training, and that’s why the engine is so pristine and also why I ran into my office chair while trying to walk towards the engine.

Rolls-Royce began VR training in March, with its two-day BR725 familiarization class. Participants join the class remotely, from their homes, offices, or maintenance facilities, logging in over the internet while wearing VR glasses and handheld VR controllers. Most sessions last about 45 minutes, followed by a break. The training is free for Rolls-Royce CorporateCare customers, and those not enrolled in CorporateCare can pay to attend.

For the VR training, Rolls-Royce has to send a big package to each participant. I was curious about what the training was like when I learned about it, so Rolls-Royce instructor and quality lead Jason Whitman arranged to ship the VR training setup to my home.

Two days later, a large Husky case arrived, containing a set of Oculus VR glasses and hand controllers as well as a powerful Windows laptop computer. Whitman emailed detailed instructions on how to set up the training session, and we arranged a time to meet in the virtual hangar.

The development of the VR training class came at a propitious time when much of the world became inaccessible for travelers due to the coronavirus pandemic. Whitman had already been working on VR training development, contracting with an outside vendor to create the complex training environment.

“I spent a lot of time with the VR company,” he said, and it took six months to get the system ready for the first class of trainees. Much of the work had to do with getting the shading, color, and texture of the thousands of parts that make up a BR725 just right—for example, to make a titanium fan blade look as if it’s really made of titanium. There was also a great amount of work to make it possible for students to break the engine down into various systems and group all the components and parts that make up each system. “It took a lot of time to graphically make the engine very pleasing,” Whitman said.

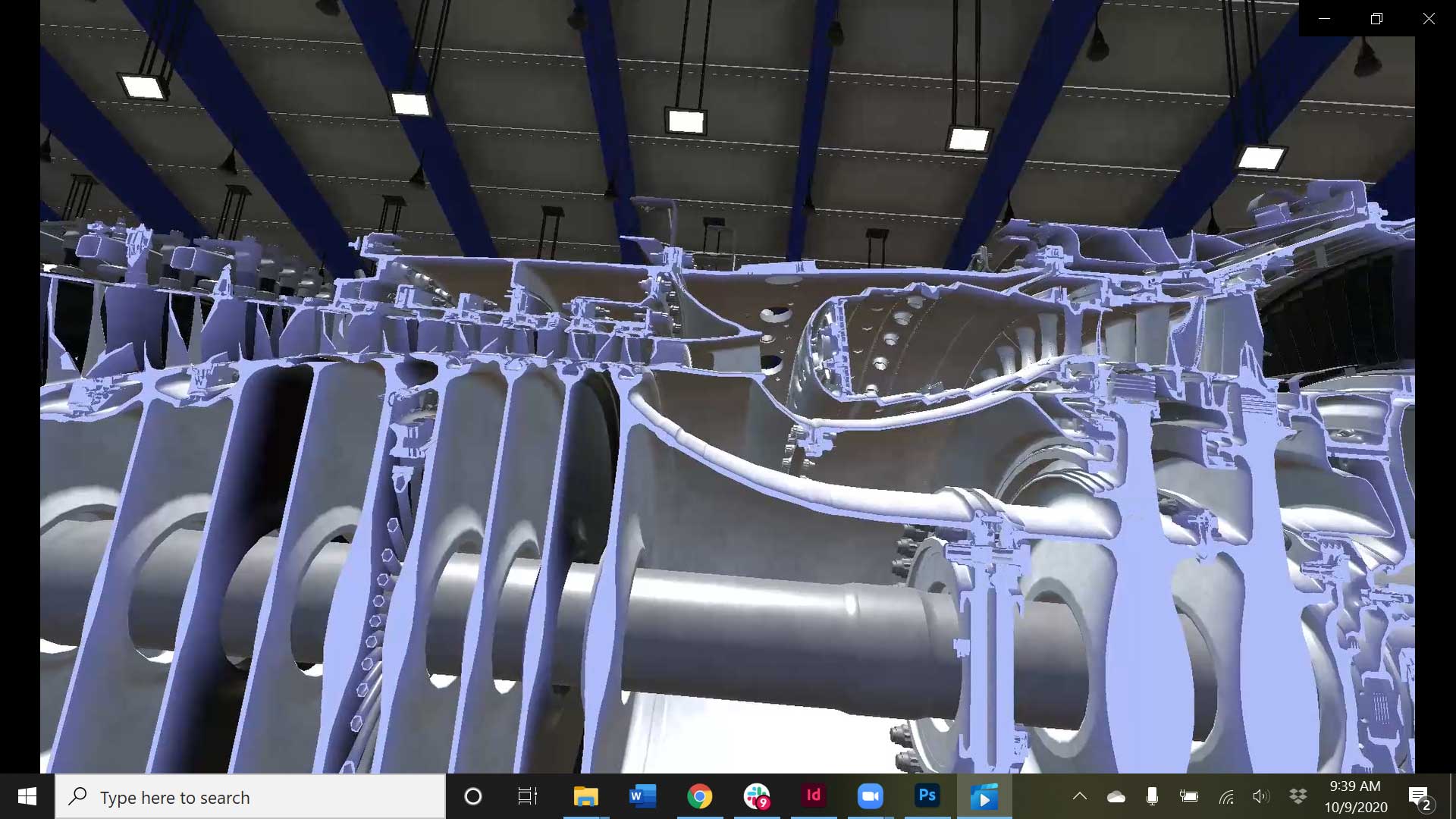

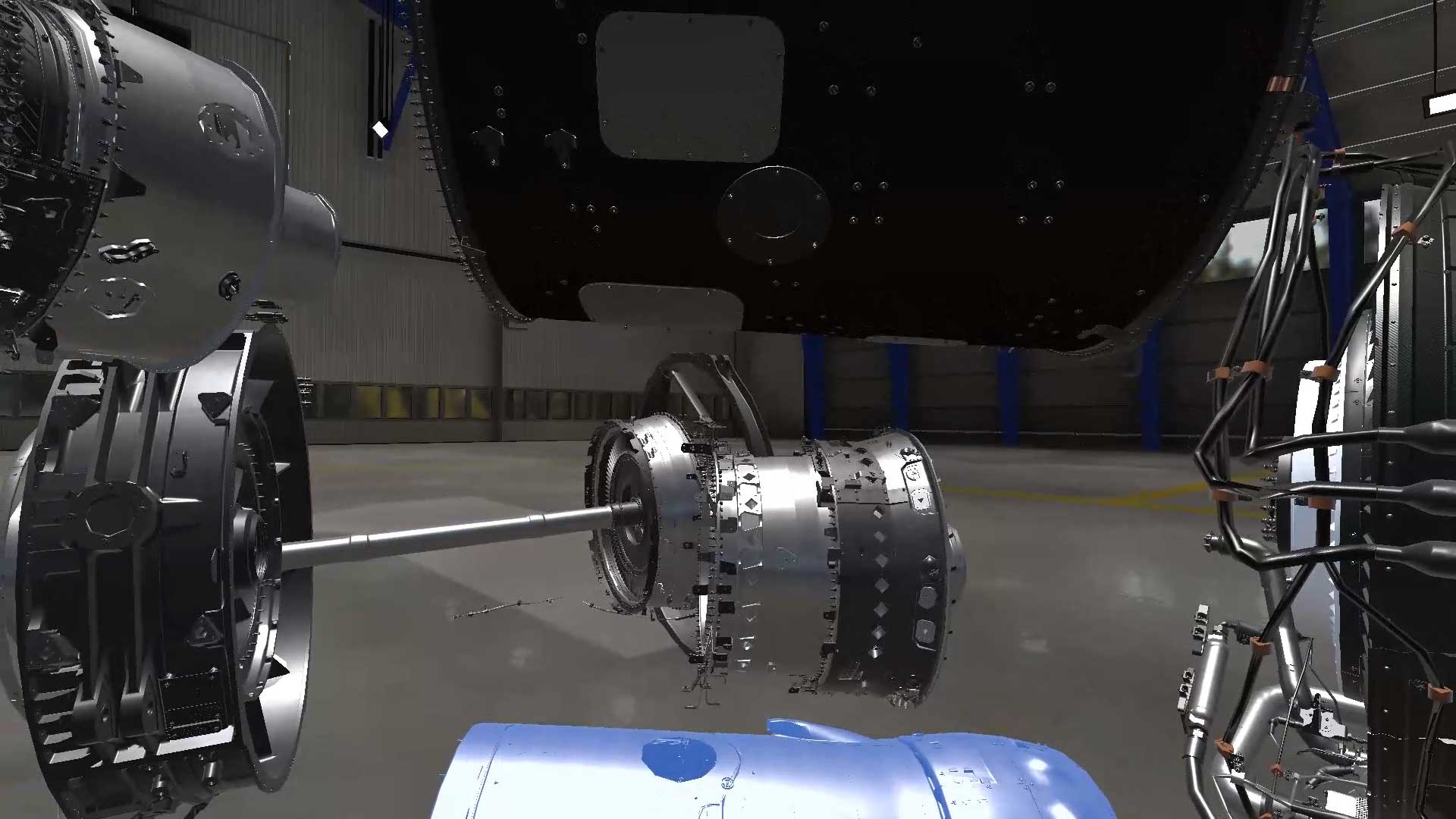

This meant not only the external appearance but also making each subassembly look real. The student can break subassemblies down in most cases to nuts and bolts. Or students can peer inside the fuel metering unit, then take it apart to see the spool valves and solenoids. “Each one of those views I went through is optimized per view to do that,” Whitman said. “It took a lot of work to be able to get to that point.” To help the computer handle the massive graphical task, he explained, “in the background, it kind of forgets the rest of the engine” while the student works on a particular component, “so the computer can prioritize parts and components. It makes it more visually pleasing.”

The benefit of VR training is that students can learn about parts of the engine that they might be able to see only if the real engine was fully disassembled. And they can see all the subsystems and components exactly as they relate to each other, either in an as-assembled view or by virtually taking them apart, assembly by assembly, piece by piece. The student can virtually dive into the engine and visually trace the way air flows through or see how the shafts and bearings relate to one another or take apart an assembly until each part and nut and bolt is floating in the air next to the engine. Both the instructor and student can use a virtual marker to draw on any part of the engine. Routine tasks are also possible, like checking the oil level or finding a part-number stamp on a part or component. Thankfully, the student can reassemble anything with just the touch of a button.

“What VR does is help students get acclimated to all the components, especially those internal ones,” Whitman said. He has been “pleasantly surprised” at the reaction from those who have taken the class. One who benefitted from the VR experience was a new Rolls-Royce software engineer who had no idea how a turbine engine works and came away with a fresh understanding. Another was an older person, an external customer. “It took him only 10 to 15 minutes to get the hang of it,” Whitman said.

As more people took the class, he found that younger students adapted quickly to the VR training. “They are very tech-savvy,” he said, “and I think this really plays into their hands. It will help them retain information and access information a lot more quickly.” In any case, most corporate operators’ technicians rarely if ever disassemble an engine. “Seeing the inside of the engine is not critical to their job, but helps them with troubleshooting and servicing.”

One great advantage of the VR training is not having to travel to a class, with all the associated logistical hassles and costs. “A lot of technicians don’t necessarily have a large training budget that allows them to fly in, stay at a hotel, et cetera,” Whitman said. “Some operators don’t have enough downtime to spare them for a week. This opens up a huge doorway to operators like that, and now they can afford to get some training.”

For now, the VR training offers the familiarization class for the BR725. “I think this is better suited to familiarization and task-based maintenance,” Whitman said. But he also sees an opportunity to use this technology for troubleshooting training or for teaching a technician how to comply with a service bulletin. “I hope next year to move forward with the troubleshooting portion,” he said. Whitman has been contacted by aviation authorities interested in how VR training can help during the Covid pandemic, perhaps even to help technicians satisfy practical requirements for their aircraft maintenance training programs. This Rolls-Royce course is not approved for any airworthiness training requirements, however, and that isn’t a goal of Rolls-Royce for the familiarization course.

During my testing of the VR training, Whitman showed me how to navigate around the engine and how to highlight and remove subassemblies and then take components apart down to the nuts-and-bolts level. Basically, it involves pointing with the hand controllers and clicking and selecting various assemblies.

The student can view the engine in various ways—for example, by virtually walking inside the engine and looking around; by using a cutaway tool to slice into the engine from the side or front; or by highlighting each subassembly and moving it off the engine and then taking a close look at its components.

The size of the room that the student is in doesn’t matter because the Oculus VR setup allows you to teleport anywhere inside the hangar without physically moving. In the view with the G650 in the hangar, the student can teleport from the floor up onto the maintenance stand next to the engine or even onto the engine’s bottom cowl, which is designed for a person to stand on. This gave me a realistic taste of what it’s like to work on the BR725.

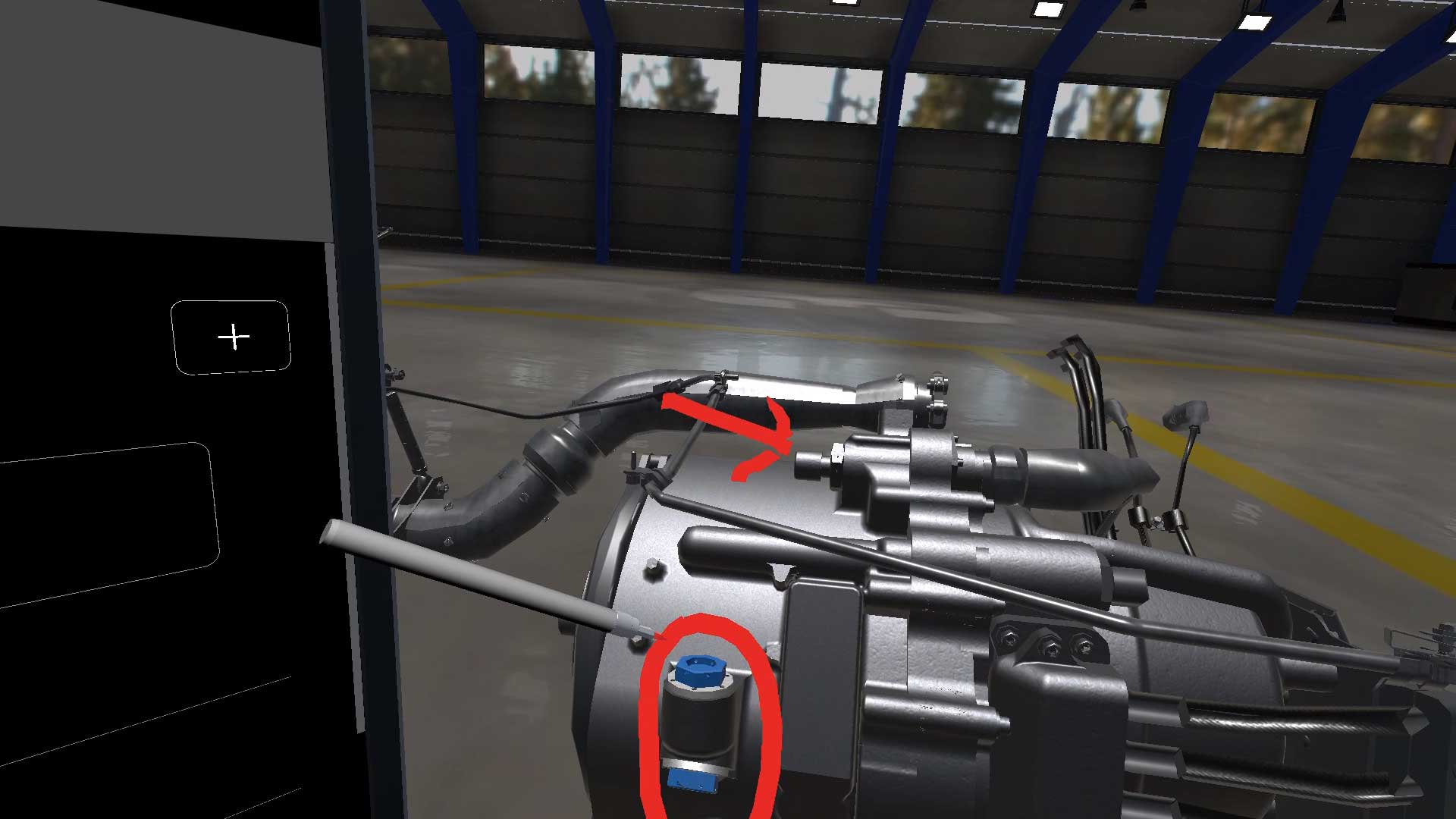

Whitman showed me a neat example of how this training can help a technician avoid embarrassing mistakes. The BR725 starter-generator is slightly pressurized, and if you need to service it with oil, you have to remove one of the plugs in the side of the housing. But if you don’t first release the pressure, as you remove the plug it will blow off in a cloud of oil and make a big mess. On the VR BR725, Whitman pulled off the starter-generator and showed me exactly where the pressure-relief button resides, so now I know about that particular tip.

Whitman also showed me the incredible level of detail in the VR model by removing a fan blade after completing the necessary disassembly steps. He flipped the virtual fan blade over and asked me to move closer, to where I could see the serial number clearly on the root of the blade. He also showed me the vortex remover tubes in the high-pressure compressor, and I could quickly grasp their function and clever design. The same was true of the stripe or “turbulator” patches on the fan blades. This is clearly no toy but a serious training tool.

The VR training is instructor-led, so someone is always there to help explain what the student is viewing. But I would prefer that the subassemblies, components, and parts be labeled. This would help students during free-play sessions. Whenever I look inside an aircraft or engine compartment, there are always components that I wonder about, and labeling would answer a lot of questions.

Another future application I’d like to see is the ability to look for indications of damage inside the engine. The VR tool does have a borescope function so the student can look inside the borescope ports, but having wear and damage to look for would add another element of reality. And perhaps eventually a virtual borescope could be used for practicing damage repair or FOD retrieval.

There is no end to the possibilities of VR training, and Rolls-Royce has taken a compelling piece of technology and turned it into a practical training tool. Anyone who takes this training will soon appreciate its benefits and capabilities.