Click Here to View This Page on Production Frontend

Click Here to Export Node Content

Click Here to View Printer-Friendly Version (Raw Backend)

Note: front-end display has links to styled print versions.

Content Node ID: 405144

Duncan Aviation Has STCs and Installation Packets for Aviation Clean Air’s Air Quality Systems

Duncan Aviation is installing a pathogen-removing, air-cleaning component from ACA (Aviation Clean Air). This component is designed to work with an aircraft’s existing environmental control system as an active air- and surface-purification system. Active means it’s not passive like an air filtration system that works only when air passes through it. As your aircraft flies, the ACA system cleans and improves air quality throughout the aircraft by killing harmful pathogens and neutralizing odors and allergens.

Because it’s not a static air filter, the system actively kills viral, bacterial, and fungal pathogens. ACA’s independent testing has found the system effective against pathogens that cause the common cold, flu (swine, avian, etc.), MRSA (methicillin-resistant Staphylococcus aureus), C. diff (clostridium difficile), E. coli (Escherichia coli), pneumonia, polio, and mold. In May 2020, an independent test by Innovative BioAnalysis found the ACA ionizer effective against the coronavirus that causes COVID-19.

In addition to pathogens, the ACA component also neutralizes potentially harmful gasses caused by fuel emissions, other VOCs (volatile organic compounds), and offensive odors caused by cooking or cleaning, cigar smoke, stagnant air, and lavatories. Pet odors are also neutralized. The system also reduces the static electricity in your aircraft that’s caused by the low relative humidity of the cabin air.

HOW DOES IT WORK?

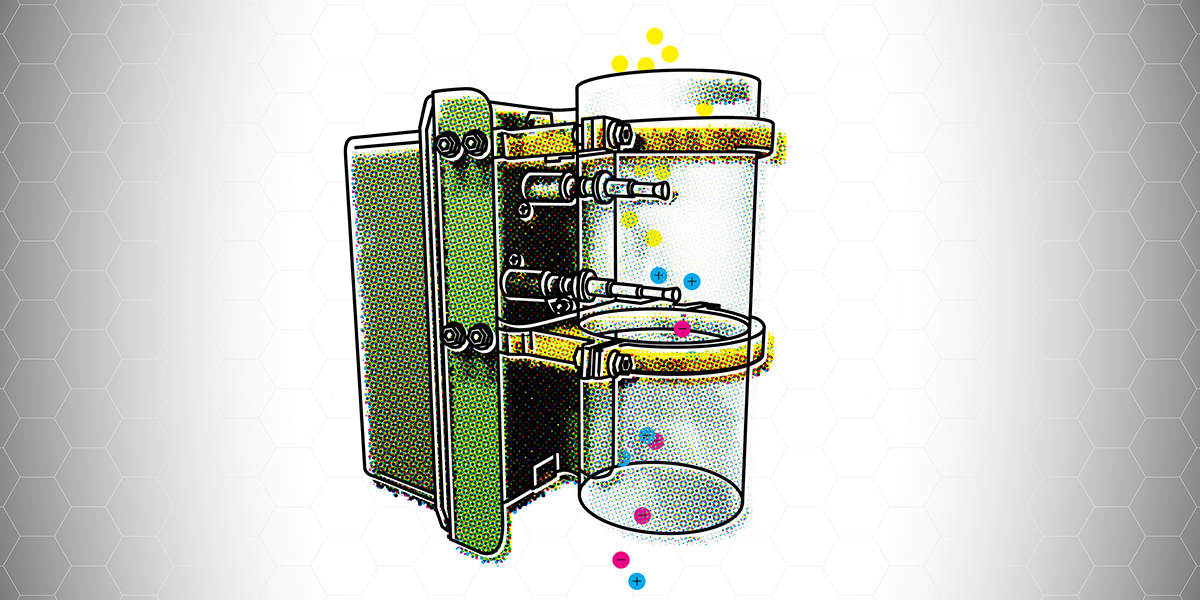

The ACA system uses a process called NeedlePoint Bi-Polar Ionization (NPBI). Ionizers like this work by emitting charged particles that attach themselves to pathogens, destabilizing and then deactivating them.

“If you want to kill a virus, you have to destabilize it,” says Epidemiologist Dr. Rachel Sippy from SUNY Upstate Medical University and the University of Florida. “A charged ion damages the virus’ envelope so the genome is exposed, deactivating the virus.”

The ACA system includes multiple ionizing components that are installed in an aircraft’s existing environmental control system. The bi-polarizing units emit electrically charged molecules, which are harmless and naturally present at all times in our environment. These molecules attach themselves to pathogens in the air and on surfaces throughout the aircraft, as well as in the air handling system itself. Unlike a one-time chemical treatment, the ACA unit provides continuous treatment of the air and aircraft surfaces when running.

The ACA units create positively charged hydrogen and negatively charged oxygen atoms, which are called hydroxyl groups. These hydroxyl groups bind to the virus’ peplomers, which are the crown-like structures that attach to receptor cells in a host. Instead, the positively charged hydrogen ion causes a chemical reaction, breaking down the proteins (glycoproteins) that protect the virus, rendering it ineffective and unable to bind to a host cell.

ACA’s independent lab test showed that 99.4% of the virus particles were inactivated within 30 minutes.

As it ionizes air, it also reduces the static electricity in aircraft that’s caused by the low relative humidity of the cabin air.

An ideal time to install this powerful system is during a scheduled maintenance or refurbishment event, but because installation takes less than 2 weeks at many of our MRO and Satellite locations, we can schedule a stand-alone event.

INSTALLATION PACKAGES FOR GLOBAL & CHALLENGER AIRCRAFT

Duncan Aviation has created an installation package for the ACA ionization system for Bombardier Global aircraft. The packages include everything necessary for installing the ACA Ionizer system in Global aircraft, including the Supplemental Type Certificate (STC), the ionizers, and Parts Manufacturer Approval (PMA) parts kits.

“Additionally, the Duncan Aviation facility in Lincoln, Nebraska, will perform the necessary modification of the air ducts for the installation. The installation of the ACA packages can be done at any of Duncan Aviation’s three main facilities (Battle Creek, Michigan, Provo, Utah, or Lincoln) or many of the Duncan Aviation Satellite Shops located throughout the United States,” said Manager of Avionics Install Line Pat Mapes. “When we say the kit includes everything, we mean every screw, nut, bolt, and switch necessary for the installation.”

The installation packages were developed for the Global aircraft, and the Duncan Aviation Engineering & Certification Services team has also developed an STC and installation package to cover the installation of the ACA Ionization System in the Challenger 300 and Challenger 350 aircraft. Kits are available for those aircraft as well. Additional certifications for other airframes are also in work and will be shared publicly as they are completed over the next few months.

“There’s been great interest in the industry for the ACA system,” said Mapes. “Our sales teams are fielding calls from customers who are interested in other makes and models of aircraft, too. This system is designed to neutralize harmful pathogens like those that cause COVID-19, so if customers want peace of mind as they fly, this is the system for them.”