Click Here to View This Page on Production Frontend

Click Here to Export Node Content

Click Here to View Printer-Friendly Version (Raw Backend)

Note: front-end display has links to styled print versions.

Content Node ID: 408659

For years, FlightSafety International has delivered the best hands-on maintenance training in the industry.

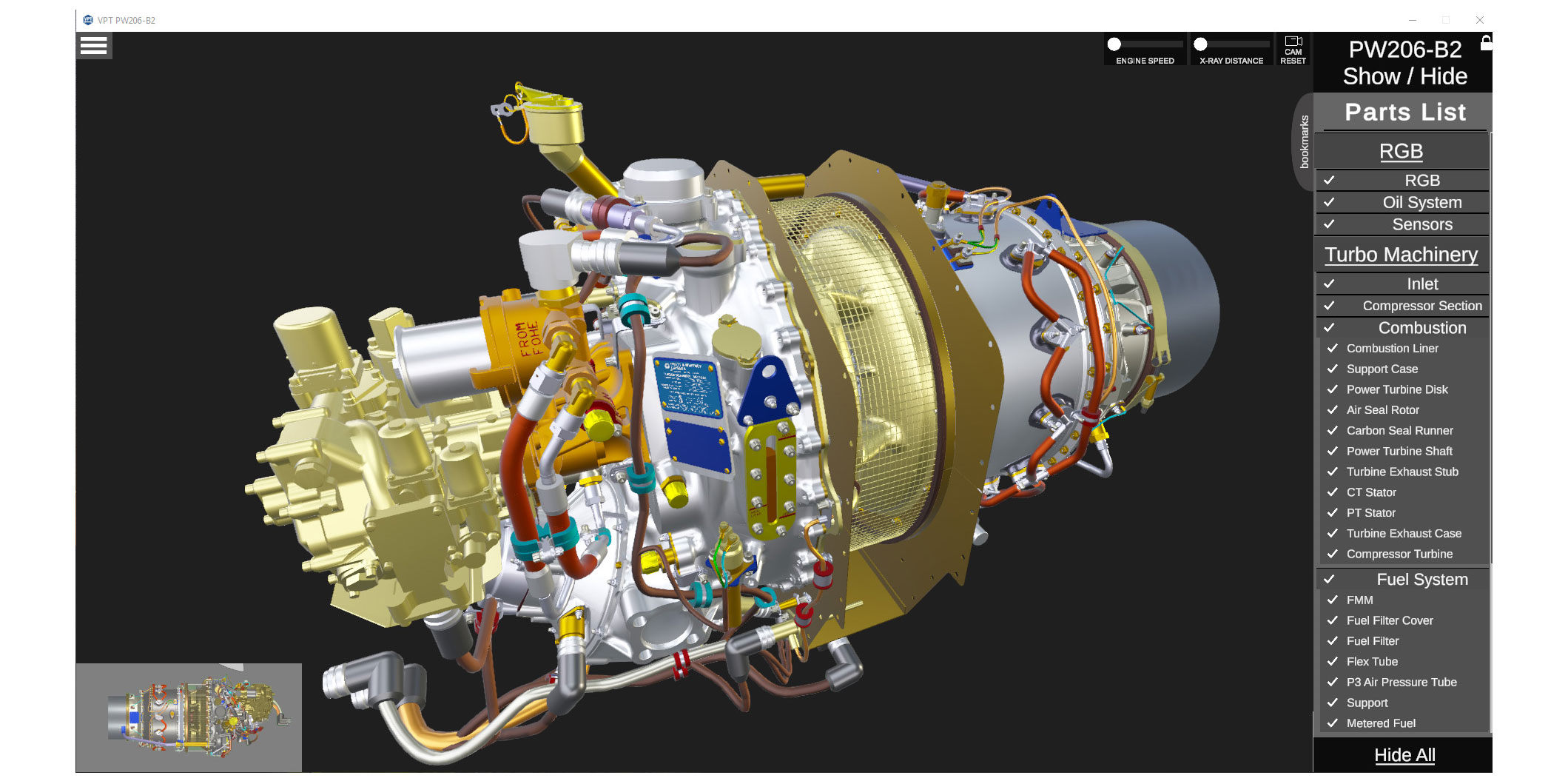

Now the aviation training leader has pivoted into the cyberworld, offering a new way to interact with components – through virtual engine training. Working with Pratt & Whitney Canada (P&WC), FlightSafety has developed cutting-edge training technology to view the engine, interactively, and explore it down to the component level.

The result is a groundbreaking method that improves efficiency, facilitates practical procedures for all students, allowing a more immersive, comprehensive training environment. This revolutionary technology was recognized by AIN as a 2021 Top Flight Award winner in Maintenance Innovation.

Creating the Program

For more than 10 years, a deep relationship has been cultivated between FlightSafety and P&WC, in support of the P&WC Engine training programs. This collaboration develops simulation of real-world operator scenarios, enhancing the training experience while ensuring currency with in-production build specs. As engines evolve, so do the virtual engine trainer models.

The team utilized the same advanced, virtual technology found in gaming engines. Much in the same way that video game players have been able to manipulate items within the game on multiple axes, the virtual engine trainer allows instructors and students to view the engine and the many individual components in any position or system grouping, in 3D and complete clarity.

Increasing Productivity and Precision

Virtual engine trainers provide a degree of interactivity that isn’t possible with heavy and difficult-to-move physical engines. Technicians can gain more intimate familiarity through interactive engine cutaways, seeing how the components and gearing work together.

The technology allows students to conduct practical maintenance procedures such as part replacement, X-ray and move functionality, further enabling students to view dynamic cross-sections of nearly every engine part.

Virtual engines allow for maintenance tasks to be simulated in guided, step-by-step processes allowing students to virtually disassemble and perform various line replacement unit change in a simulation.

Integrating the virtual experience into standard maintenance courses gives technicians the full picture of how each component works, complementing practical hands-on and classroom instruction.

Testing and Inspecting Virtually

One of the greatest functionality improvements with the virtual engine trainers is the ability to simulate an engine inspection during borescope training. The virtual engines are synthetically altered to represent various degrees of damage found in a P&WC turbine engine. Students are challenged to assess engine damage and are evaluated based on engine health and dispatchability.

It is a similar concept as in FlightSafety’s simulator training for pilots where potentially hazardous scenarios can be safely simulated for pilots to hone their skills. With the virtual borescope training, students can more easily see many more types of damage, or the signs of wear and tear than they could on a physical component. Most physical models are present only as ideal-state engines, depriving technicians of what they’re likely to experience in real-world scenarios on the line.

The virtual engine trainer fidelity is such that certain regulatory agencies have approved the virtual engine trainer as a method of assessment for up to 50 percent of practical engine training. This tool allows students to meet requirements more quickly and efficiently, thereby enhancing the value of the training provided.

FlightSafety currently offers Virtual Engine Training for P&WC equipment at 12 locations, including the United States, Australia, Brazil, Canada, China, France, and India. Courses cover the PT6, PT6A, PT6E, PT6C, PT6T PW206, PW300 and PW800 series. The innovative program continues FlightSafety’s commitment to creating the most well-trained technicians in the industry, empowered with practical and strategic knowledge.