Click Here to View This Page on Production Frontend

Click Here to Export Node Content

Click Here to View Printer-Friendly Version (Raw Backend)

Note: front-end display has links to styled print versions.

Content Node ID: 414339

GE Aerospace has outlined what is one of the company’s most extensive technology development roadmaps in its more than 100-year history. Multiple ground and flight tests planned this decade will seek new, breakthrough technologies for use in next-generation commercial aircraft engines that could enter service beginning in the mid-2030s.

Advanced engine architectures such as open fan, hybrid electric propulsion systems, and new compact engine core designs—just some of the technologies that will be demonstrated on test stands over the coming years—are all key programs to watch in 2023 and beyond.

In addition to maturing these technologies for flight readiness and new products, GE Aerospace also supports efforts to increase use and availability of alternative fuels, such as Sustainable Aviation Fuel (SAF) and hydrogen.

Revolutionary technologies and alternative fuels both have critical roles to play in meeting the aviation industry’s long-term climate goal of net-zero CO2 emissions by 2050 for commercial flight.

Here, we’ve laid out GE Aerospace’s top innovations and industry-leading efforts to watch in the march toward net-zero.

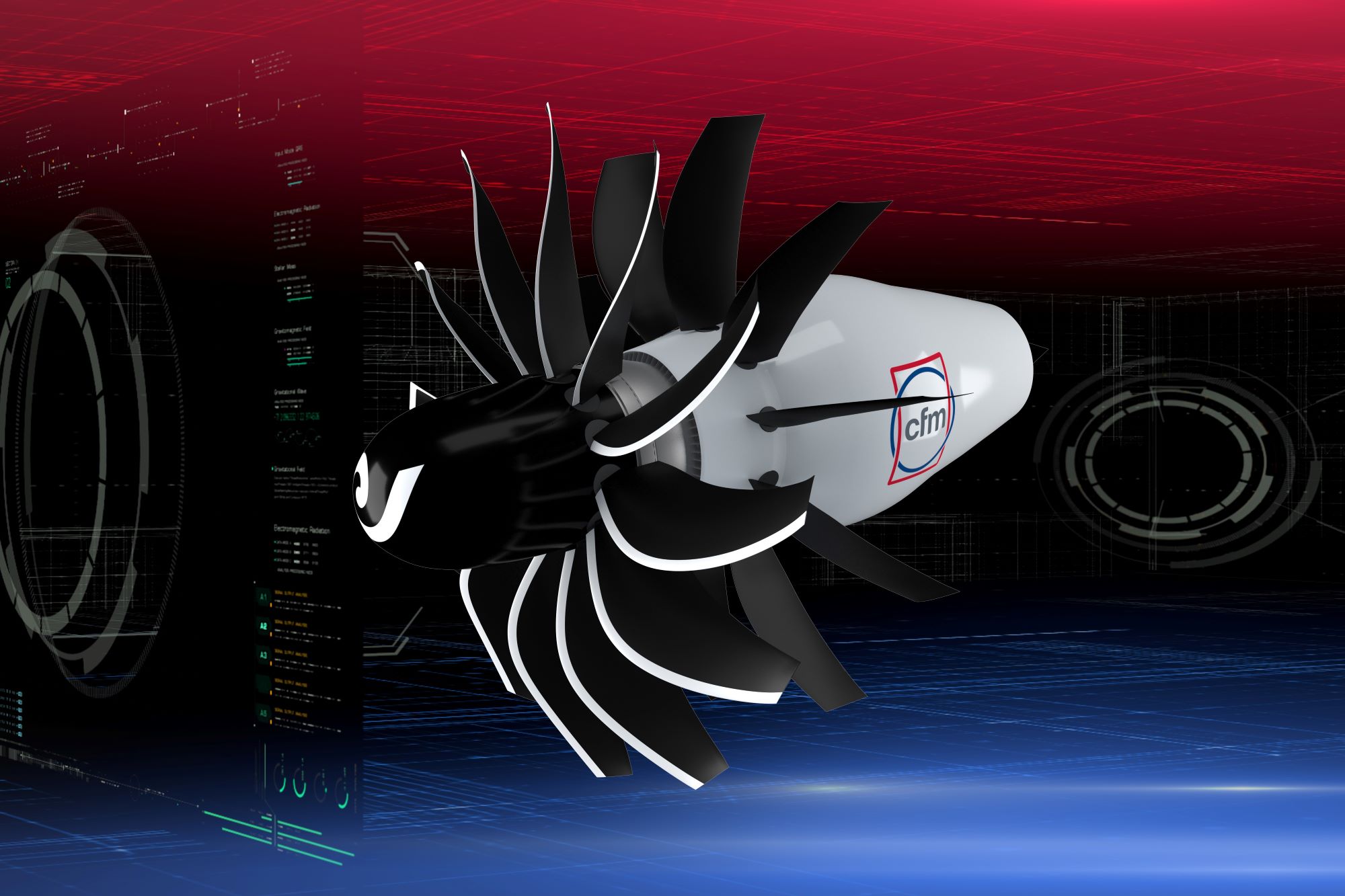

Open fan and the CFM RISE program

If you ask GE Aerospace's chief engineer Chris Lorence, the time for open fan is now. Why? Since GE Aerospace first flew an unducted fan in the 1980s, the open fan engine architecture has been made simpler and lighter with new approaches such as single-stage rotating carbon fiber composite fan blades and stationary outlet guide vanes. He explains more about his views on open fan here.

The open fan design is one of the advanced engine architectures CFM International, a 50-50 joint company between GE Aerospace and Safran Aircraft Engines, is exploring through the CFM RISE program. The parent companies came together in June 2021 to launch the RISE program with a target of more than 20 percent better fuel consumption and lower CO2 emissions compared to today’s most efficient engines. Technologies matured as part of the RISE program will serve as the foundation for the next-generation CFM engine that could be available by the mid-2030s. Central to the program is state-of-the-art propulsive efficiency.

A more electric future

Even before NASA announced in September 2021 the selection of GE Aerospace for its Electrified Powertrain Flight Demonstration (EPFD) program, GE Aerospace had been advancing electrification of aircraft and engine systems for more than a decade. During that time, GE Aerospace engineers matured individual components of a hybrid electric system, including motors, generators, and power converters.

Now, the jet engine maker and aircraft systems company is taking what it’s learned in laboratories about making an integrated electric machine and readying it for ground and flight tests planned for the mid-2020s.

Through the total $260 million EPFD program with NASA, GE Aerospace is maturing a megawatt-class hybrid electric powertrain to demonstrate flight readiness for single-aisle aircraft using a modified Saab 340B testbed and GE Aerospace's CT7turboprop engines. GE Aerospace is partnering with Boeing, which will support the program’s flight tests and has selected BAE Systems to design, test, and supply energy management components.

Smaller core, greater efficiency

One of the enabling technologies being studied in CFM’s RISE program is a compact engine core. In another multimillion-dollar program with NASA announced in late 2021, GE Aerospace was awarded contracts to test and mature new jet engine core designs, including compressor, combustor and high-pressure turbine technologies to improve thermal efficiency. Continued development of Ceramic Matrix Composites, an advanced, heat-resistant material, is also a key part of the effort to improve fuel efficiency and thereby reduce emissions. GE Aerospace expects this effort to lead to a ground test later this decade.

Sustainable Aviation Fuel (SAF) testing

GE Aerospace’s long history of SAF testing in collaboration with industry partners includes the first commercial demonstration flight of biofuel in 2008, the first commercial aircraft flight with 100% SAF in 2018, SAF engine emissions testing, and the first passenger experimental flight in 2021 with 100% SAF in one of the two engines.

SAF has the same chemical composition as the jet fuel most commonly used today. The key difference is instead of being made from fossil-based sources, SAF is made from partially or completely renewable sources. The use of renewable feedstocks and processes reduces net CO2 emissions over the entire fuel lifecycle.

SAF is currently approved for use in blends up to 50% with conventional jet fuel. Efforts are underway to standardize 100% drop-in SAF, which doesn’t require blending and is compatible with existing aircraft and infrastructure.

For example in 2022, GE Aerospace completed successful ground testing of its Passport long-range business aviation engine using 100% SAF. The Passport engine can operate on approved SAF today, and the recent testing shows the capability of the engine to run on 100% SAF.

Pioneering hydrogen combustion

The announcement made in February 2022 that CFM and Airbus are collaborating on a hydrogen demonstration program will be informed in part by GE Aerospace’s experience with hydrogen fuels in land-based gas power turbines. GE Aerospace has more than eight million operating hours of experience with hydrogen fuel blends, including with aeroderivative engines.

CFM and Airbus plan to conduct ground and flight tests this decade of a direct combustion engine fueled by hydrogen. To do so, CFM will modify the combustor, fuel system, and control system of a GE Passport™ turbofan to run on hydrogen. The engine was selected because of its physical size, advanced turbo machinery, and fuel flow capability. It will be mounted along the rear fuselage of the flying testbed to allow engine emissions, including contrails, to be monitored separately from those of the engines powering the aircraft.

CFM will execute an extensive ground test program ahead of the A380 flight test.

“We will fly a modified engine to learn the art of the possible and to prove out the technologies,” said Mohamed Ali, vice president and general manager of engineering for GE Aviation. “Is hydrogen harder? Yes. Is it doable? Absolutely. And we are building on tremendous experience, and I am actually very encouraged by the inventions we have already made to address those challenges.”