Click Here to View This Page on Production Frontend

Click Here to Export Node Content

Click Here to View Printer-Friendly Version (Raw Backend)

Note: front-end display has links to styled print versions.

Content Node ID: 414527

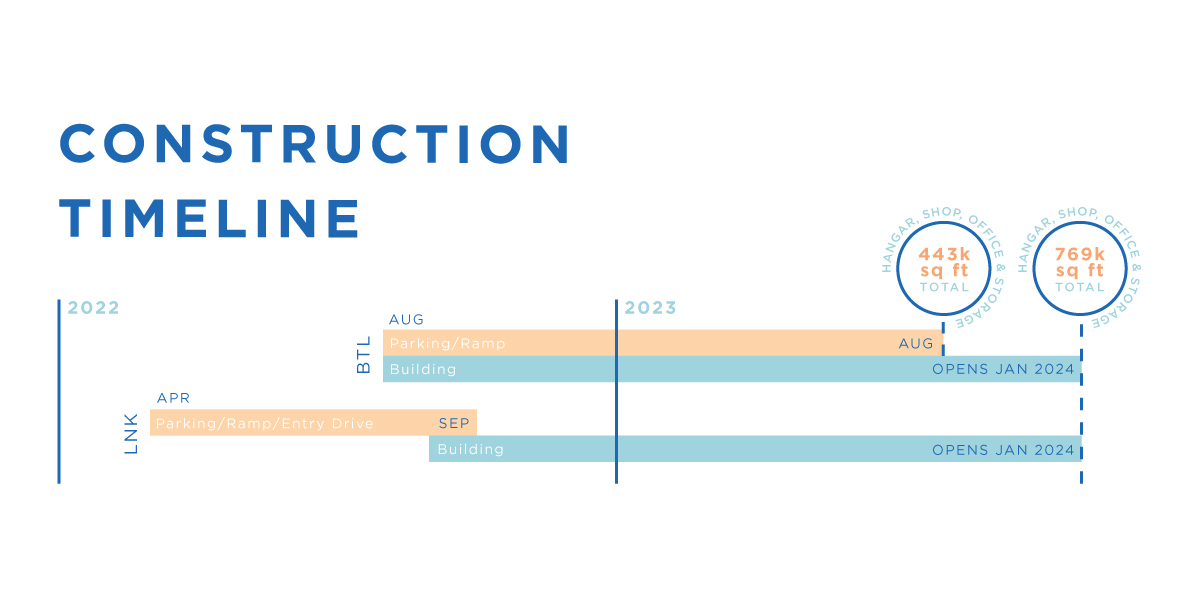

Since Duncan Aviation announced expansion plans for new hangars at its Lincoln, Nebraska (LNK), and Battle Creek, Michigan (BTL), locations more than a year ago, dirt has been moved, foundations have been poured, steel has been erected, and progress has been swift. The new hangars are expected to open in January 2024.

The company is working with long-time partner Tectonic Management Group and is using the latest in green construction technologies to build at both locations a 46,000-square-foot hangar with 32-foot-high hangar doors and an additional 62,000-square-foot, two-floor wing for storage and backshops. The total expected investment for both is approximately $66 million.

“Duncan Aviation has consistently reinvested at least 80 percent of its profits back into the company and its team members in the form of facility expansions and capital improvements,” says Jeff Lake, President and CEO of Duncan Aviation.

Sustainability features for the new hangars and buildings include light harvesting, radiant floor heating with energy-efficient boilers, LED lighting fixtures with sensors and automatic dimming, and more. Frank Jacobsen, Vice President with Tectonic, says the buildings and systems will perform more than 25% better than standard energy codes.

When construction is complete, Duncan Aviation will have 769,000 square feet of hangar space and shop, office, and storage areas in Lincoln. The Battle Creek location will have 443,000 square feet of hangar, office, shop, and storage space.

The increased footprint for aircraft projects will require the addition of 65 to 75 team members at each location over a five-year period, Lake says. Those jobs will include airframe technicians as well as positions in interior, installations, engine, paint, and the support shops.

Battle Creek, Michigan

Andy Richards, Chief Operating Officer of Duncan Aviation’s Battle Creek location, says the expansion is a direct result of the excellent service and support operators have received.

“Over the past 67 years, Duncan Aviation has grown an increasingly loyal and diverse customer base that depends on the quality service and friendly customer experience provided by our teams,” Richards says. “The expansion will increase our ability to attract even more customers to the Duncan Aviation family.”

Lincoln, Nebraska

Mike Minchow, Chief Operating Officer of Duncan Aviation’s Lincoln location, says the new hangars will be the largest Duncan Aviation has built to-date. “We are excited not only to be building additional hangars to give us more room and greater flexibility in the near term but to continue to grow with where the market is headed both in aircraft size and the number of inspections expected in the future. In addition, we are excited to create up to 75 career opportunities for new team members in Lincoln and Battle Creek, and we have already started to recruit team members to fill the additional positions.”

Why Build?

The demand for the safety and flexibility that business aviation travel provides has continued to increase, as has the average size of business aircraft, Lake explains. This results in increased demand for the hangar space required to complete requested airframe, engine, interior, paint and avionics modifications for the business aircraft fleet. “Looking to the future, we know that in order to meet current customer requests and needs, Duncan Aviation will need more hangar facilities,” he says.

Fun Facts About The Construction

In addition to the hangar and two-story support buildings, the Battle Creek construction is also adding a new, stand-alone vehicle maintenance building and a paint hangar annex. The vehicle maintenance building features three vehicle bays, two of which are capable of handling our largest fuel and de-ice trucks. The paint hangar annex will allow for additional hex chrome decontamination.

The expansion adds more than 102,000 square feet of space to the existing facility. Construction facts include the following:

- The new hangar will have 1,066 tons of steel in it, just over 2 million pounds

- The total project has just under 15,000 cubic yards of concrete or roughly 1,500 truckloads. (For comparison this would equate to 45 miles of sidewalk if you were to pour this same quantity as a 5-foot-wide city sidewalk)

- The project has more than 120 tons of concrete reinforcing (rebar and wiremesh)

- The dowels used in the concrete are 18-inches long, and if you stack them up end-to-end would equal seven miles

- There will be 10 miles of sawcut contraction joints in the ramps

In Lincoln, the expansion include moving the exterior Learjet 35, N72DA, historical display to a new location. Additional interior features include additional customer offices, a new lunchroom, and a larger training classroom for leadership and professional development classes.

The expansion in Lincoln adds 108,000 square feet of space. Construction facts include the following:

- 1,000 dump truck loads removed 10,000 cubic yards of existing pavement

- 13,000 dump truck loads moved approximately 155,000 yards of soil

- 5,100 feet—nearly 1 mile—of new storm drainage will be installed

- More than 51 truckloads of steel totaling 870 tons was used

- 115 new trees will be planted