Click Here to View This Page on Production Frontend

Click Here to Export Node Content

Click Here to View Printer-Friendly Version (Raw Backend)

Note: front-end display has links to styled print versions.

Content Node ID: 408401

It is widely recognized across the aviation industry that we must collectively move to a more sustainable footing and that such an effort must begin with airframe and powerplant OEMs. Aviation today contributes 2-3% of CO2 emissions; some suggest that if left unchecked the figure could rise to 18% by 2050. Obviously, no one is prepared to allow that to happen, least of all Pratt & Whitney.

We have always been a leader in sustainability—long before it reached the current tipping point—simply because the use of less fuel delivers customer value in the form of lower operating costs. As we design, manufacture and service aircraft engines we are constantly reminded of the need to deliver customer value, and that will never change. Historically, every new generation of our engines delivers greatly improved fuel consumption.

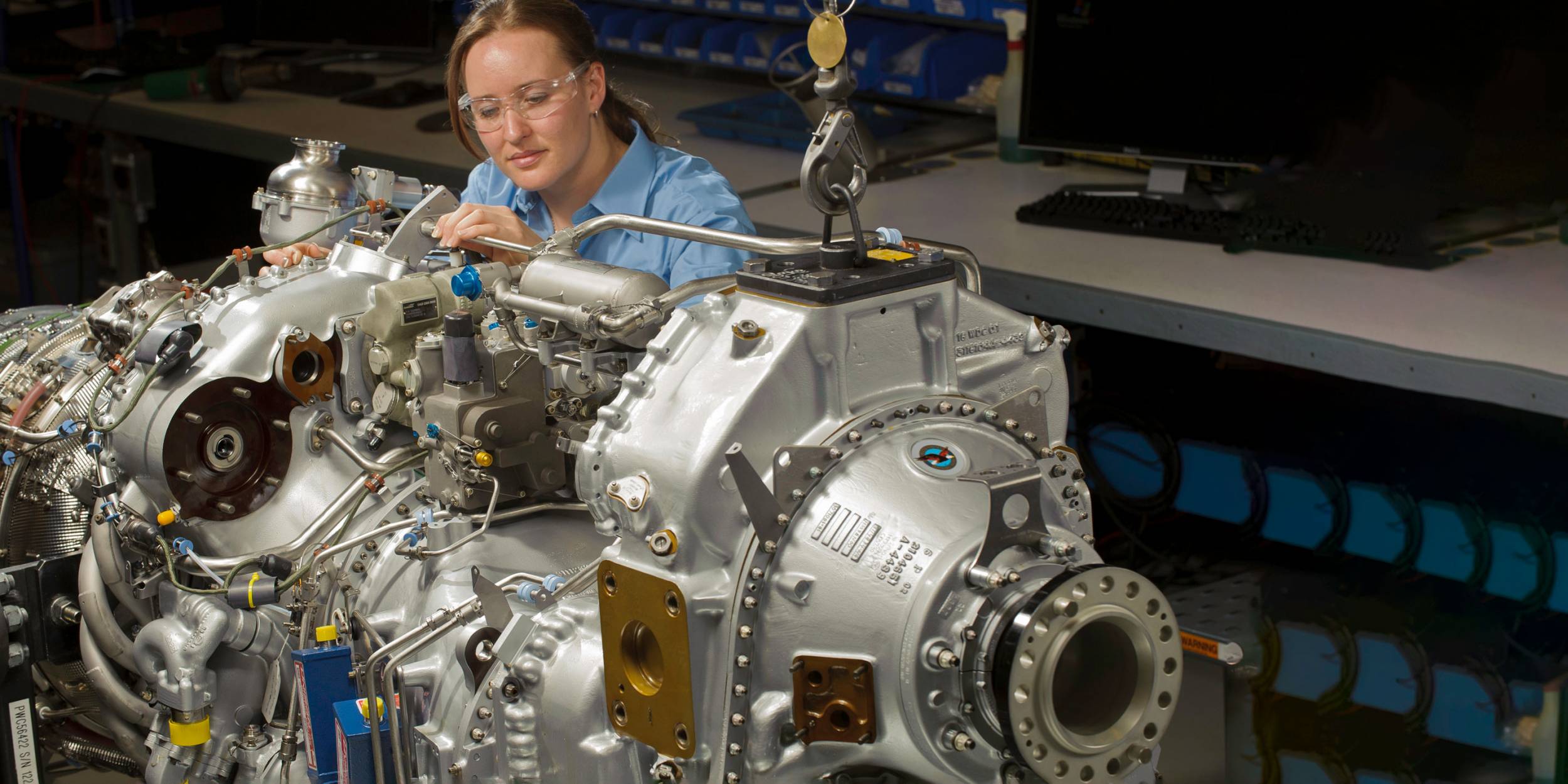

Time and again throughout our near-century of experience, we have overcome headwinds to achieve significant technology breakthroughs – all within the context of certifying an average of four new engines a year. Consider the new PW127XT engine series which offers regional airline operators 40% more time on wing and a 20% reduction in maintenance costs, plus a 3% improvement in fuel consumption.

Also, thanks to a revolutionary geared turbofan architecture, our GTF™ engines which power commercial airliners save up to 20% in fuel and CO2 emissions, and up to 50% in regulated emissions, with up to a 75% smaller noise footprint.

So, our bona fides are well documented and we are determined that our track record of achievement will continue. Let me share how we are working to achieve greater sustainability through our engines.

Three Pillars

We focus on three broad pillars – the development of smarter technology, the use of cleaner fuel, and the processes and facilities we use to manufacture and service our products – what we refer to as creating a greener business. All of this constitutes our belief that sustainability is a key corporate value. For this article, I will focus on the first two.

Amidst our sustainability pursuits, we never lose sight of the safety imperative—the reliability of our engines to perform their missions safely anywhere in the world. This focus on safety has driven our success for decades and will do so for many more to come.

Regional Hybrid Electric Flight Demonstrator

We are bullish on the prospects for a hybrid engine that combines an electric motor with a fuel-burning engine. Last year, we announced our regional hybrid-electric flight demonstrator program, with a $163 million CAD investment, supported by the governments of Canada and Quebec.

The hybrid-electric demonstrator targets a 30% reduction in fuel burn and CO2 emissions, compared to a modern regional turboprop airliner. This will be enabled by optimizing performance across the different phases of flight. In the hybrid-electric arrangement, an electric motor and thermal engine work in tandem, providing an electric power boost during takeoff, when the engine power is needed the most.

This allows the size of the thermal engine to be reduced and optimized for cruise power, reducing overall aircraft weight. This weight reduction, along with the need for less heavy fuel, helps accommodate the weight of the battery.

P&WC is working with De Havilland Canada to integrate this hybrid-electric technology into a De Havilland Canada Dash 8-100 flight demonstrator with a 30-passenger capacity. This demonstrator will include an advanced electric motor and controller from Collins Aerospace. Collins Aerospace and Pratt & Whitney are sister companies operating under Raytheon Technologies Corporation. In May, 2022, we announced that H55 S.A. will provide the battery systems for the program. The Swiss-based company’s core competencies are in developing propulsion and energy storage solutions which are modular, lightweight, and safe.

The companies are targeting ground testing of the demonstrator engine in 2022 with flight testing to follow in 2024.

The Government of Canada is supporting our demonstrator program through its Strategic Innovation Fund, part of its green recovery plan. It is a great example of government and business working together to drive innovation in aerospace – especially since aerospace is such an important industry in Canada.

Strong, Effective Collaboration

The regional hybrid-electric flight demonstrator program is also a showcase for the collective expertise found within Raytheon. While Pratt & Whitney has pushed the boundaries of propulsion technology for nearly a century, Collins Aerospace is a leader in the design, manufacture, and integration of electrical aircraft systems, as well as a vast array of other aircraft components.

We view the hybrid-electric demonstrator as a learning platform that we can then scale up or down based on market requirements. From our perspective, aircraft of under 10 seats flying on short missions of 30 minutes or less hold the most potential for 100% electrification. We see hybrid-electric engines in the 30- to 50-seat capacity as the “sweet spot” as we advance the power density (electric output per kilogram of battery) of batteries. Other technology injections are being looked at to push hybrid-electric engine capability into the 70+-seat capacity size.

Our demonstrator is a parallel system whereby the electric motor and thermal engine operate in combination to create optimized power efficiency. We are also looking at certain technologies where an on-board thermal engine is used to charge batteries while in flight while the propulsion power is generated uniquely from the electric motors. This option would likely mean multiple electric motors on the aircraft.

Sustainable Aviation Fuel—SAF

Moving from the engine to what fuels it, sustainable aviation fuels will play a key role in helping create a more environmentally sustainable aviation industry. Our entire engine fleet is substantially ahead of the curve, being SAF compatible up to 50% blend limit for well more than a decade. We are collaborating with several OEMS on further SAF developments to maximize the use of SAF in the future.

For example, we are working with our OEM customer ATR on achieving 100% SAF compatibility. In June, ATR flew an ATR 72 aircraft (owned and operated by Braathens Regional Airlines) with two of our production configuration PW127M engines using 100% SAF in both engines with stellar results. This was the first time a test of this type has been conducted. Earlier in the year, ATR had flight tested one of our PW127XT-M engines on 100% SAF with the other engine burning standard jet fuel. Embraer has also flown one of its E-Jets E2 aircraft with one GTF engine running on 100% SAF, again with excellent results. The GTF team had previously conducted a series of ground runs using 100% SAF.

These steps are important in establishing industry standards and acceptance of 100% SAF.

Hydrogen Fuel

Beyond SAF, we believe that hydrogen represents a zero-carbon opportunity – providing the industry finds solutions to infrastructure challenges relating to hydrogen production, storage, and distribution systems. It is important to point out that engine technology to burn hydrogen is not a limiting factor and Pratt & Whitney is capable of converting our engines to allow for direct combustion of gaseous H2.

One promising aspect is a combustor designed specifically for burning hydrogen which would decrease nitrogen-oxide (NOx) emissions in contrails and improve overall efficiency with a next-level heat exchanger.

Pratt & Whitney was selected by the United States Department of Energy advanced research arm (ARPA-E) to develop a Hydrogen Steam-Injected, Inter-Cooled Turbine Engine (HySIITE engine). The project will use liquid hydrogen (LH2) combustion and water vapor recovery to achieve zero in-flight CO2 emissions, while reducing NOx emissions by up to 80% and reducing fuel consumption by up to 35% for next-generation single-aisle aircraft.

Delivering Value

As you can see, we are tackling the challenges of sustainable aviation on multiple fronts, as befits a company with a near-one-hundred-year track record in propulsion. It is our fundamental belief that sustainability will be achieved through industry collaboration and through technology advancements that are additive and complementary, all – of course – within the context of reasonable costs.

This approach allows us to deliver value to society in lock step with our determination to provide value to our customers.